Sandvik Coromant Releases Two New Insert Grades for Steel Milling

Press Release Summary:

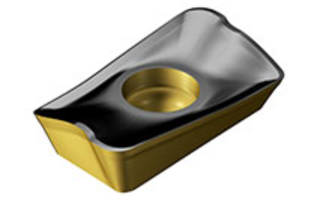

Sandvik Coromant’s GC4330 and GC4340 are designed to increase resistant and tool life and be resistant to thermal cracks. GC4330 has applications for semi-finish face milling and the GC4340 has applications for rough shoulder and groove milling.

Original Press Release:

Latest Milling Grades Improve Tool Life and Process Security

Cutting tool and tooling systems specialist Sandvik Coromant is launching GC4330 and GC4340, two new insert grades for steel milling. With the development of advanced production technologies, such as a new substrate, Inveio™ coating and an improved post-treatment technology, the new grades provide great opportunities to substantially increase tool life and process security compared to the previous generation of grades, GC4230 and GC4240, which will now be superseded.

Manufacturers face many challenges when milling ISO P workpieces. For instance, some hard and abrasive steels can generate wear along the flank face of the insert, especially at higher speeds and with a longer time in cut. Additionally, machining in unstable conditions due to compromised clamping or long overhang elevates the risk of insert chipping, while thermal fluctuation during machining, especially under wet conditions, can cause crack formation and subsequent sudden breakages.

“Our new grades overcome these issues in many ways,” states Magnus Engdahl, Product Application Manager at Sandvik Coromant. “For instance, the optimized Inveio™ coating increases wear resistance and tool life dramatically, without jeopardizing security. With its uni-directional crystal orientation, the coating has a high resistance to thermal cracks, which in turn promotes long and reliable tool life, a factor further supported by a new post-treatment process that strengthens the insert by modifying its mechanical properties.”

A newly developed substrate provides well-controlled grain size distribution, which results in more reliable and predictable tool behavior. Additionally, consistent tool life is supported with higher narrow edge-rounding (ER) tolerance. Increased tool life will deliver reduced cost per component, while improved process security brings predictable performance and less downtime, not to mention higher component quality.

GC4330 is a medium hard grade and is the First choice for roughing to semi-finish face milling, with the tough GC4340 grade preferred for rough shoulder milling and groove milling. Wet and dry machining is supported, although dry machining is recommended.

Both GC4330 and GC4340 are available in the following product families: CoroMill® 390 and CoroMill® 490 for shoulder milling; CoroMill® 345 and CoroMill® 745 for face milling; CoroMill® 210 for high-feed milling; CoroMill® 200 for profile milling; and CoroMill® 331 for grooving and parting off. Although the grades are optimized for steel, they are also suitable for mixed production involving ISO K (cast iron) and ISO M (stainless steel) workpieces.

For more information please visit www.sandvik.coromant.com/en-us/products/milling-inserts-grades-steel

Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 7,900 staff, and is represented in 150 countries.

For more information visit www.sandvik.coromant.com

Follow us on social media:

Facebook | YouTube | Twitter | LinkedIn | Instagram

Contact details for editorial inquiries

Angela Roxas, PR & Sponsorships – Sandvik Coromant

Phone: (201) 294-9160

Email: angela.roxas@sandvik.com