Safety Light Curtain offers protective heights from 12-72 in.

Press Release Summary:

Series C 4000 self-contained, non-contact light curtain features sensing resolutions of 14, 20, 30 and 40 mm with scanning ranges up to 19 m and response times as short as 7 ms. Application Diagnostic Output provides status indication of Output Signal Switching Devices. Up to four areas of fixed blanking, floating blanking or combination can be utilized simultaneously. Filtered front window provides immunity to ambient light, weld flash and strobe lights.

Original Press Release:

SICK's Latest Version of C 4000 Safety Light Curtain

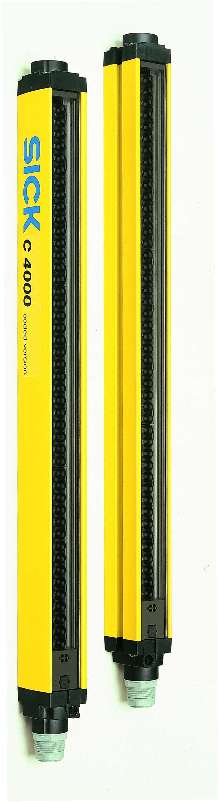

SICK's latest version of their C 4000 series (Step II) safety light curtain is a self-contained, non-contact, control reliable (Type 4) machine safeguarding device that combines high resolution with small size and increased functionality. These units feature a small profile cross-section with protective heights ranging from 300 to 1800 mm (12 in to 72 in). Sensing resolutions of 14, 20, 30 and 40 mm are available with scanning ranges up to 19 m (60 ft). They are designed for point-of-operation, perimeter, entry/exit and area machine safeguarding applications.

The latest version of SICK's C 4000 safety light curtain includes a variety of new cost-saving features:

o Emergency Stops and Safety Interlock Switches can be connected directly to the C 4000 receiver unit when the safety output requirements of these devices correspond to the same safety outputs of the safety light curtain, saving the additional cost of wiring and separate relays

o Status information is now available through an Application Diagnostic Output (ADO) that can provide status indication of the Output Signal Switching Devices (OSSDs - safety outputs), whether the front window is dirty and needs to be cleaned, or when the Emergency Stop button has been pressed

o "Reset" and "Reset Required" connections are now available on the extension plug of the C 4000 receiver unit, saving the cost of cabling back to the control cabinet

o External Device Monitoring (EDM / Relay Backchecking) may allow the user to connect the OSSDs from the C 4000 receiver unit directly to the final switching device, saving the cost of additional safety relay modules

o A "Teach" button can be configured on the C 4000 for fixed or floating blanking applications.

o Up to four areas of fixed blanking, floating blanking or a combination can be utilized simultaneously. The use of object detection is also selectable in floating blanking applications.

o The seven-segment diagnostic display can be configured so that the diagnostic messages are always "right side up" regardless of how the unit is mounted vertically.

o Very fast response times (as short as 7ms) reduce the minimum safety distance required in many applications.

The C 4000 is housed in a rugged aluminum extrusion with a filtered front window that provides immunity to ambient light, weld flash and strobe lights. Unit installation is a snap with swivel-mount brackets and cable connections for field wiring.

Units are pre-configured, right out of the box, for guard-only machine safeguarding, automatic reset (external reset), EDM=OFF and short range without requiring the use of a computer. If desired, these and other settings can be changed using SICK's intuitive and easy-to-use, Microsoft Windows-based, CDS Configuration and Diagnostic Software tools.

The C 4000 series is the only safety light curtain from any manufacturer that has been tested and certified to the latest international standard for plant safety, IEC 61508. These units have been certified to Safety Integrity Level (SIL) 3, the highest possible rating attainable for a safety light curtain.

SICK's C 4000 safety light curtains provide control reliable safeguarding, while allowing unrestricted access to machines, making material placement, work piece removal or maintenance possible at all times. A cascading configuration option allows connection of up to three light curtain pairs with parameters that are individually set on each curtain. Typical applications include finger, hand or body protection in press, robot, assembly machine, packaging machine and pick and place machine applications.