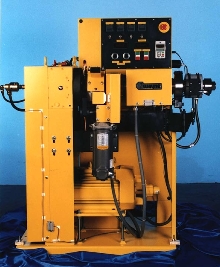

Rubber Extruders come in floor or tabletop versions.

Share:

Press Release Summary:

Yellow Jacket processes rubber into extruded tubing, profiles, wire insulation, cable coating, sheet, film, and rod. Standard screw sizes are 5/8, 3/4, 1, 1 1/4, 1 1/2, 1 3/4, 2, 2 1/2, 3 1/2, and 4 1/2 in. Extruders have easy to clean, slide mounted roll for feeding rubber strips to extruder screw and ratio controlled drive system. Water-cooled feed sections are available in standard, tangential, and tapered lid styles. Instrumentation for process control is available.

Yellow Jacket processes rubber into extruded tubing, profiles, wire insulation, cable coating, sheet, film, and rod. Standard screw sizes are 5/8, 3/4, 1, 1 1/4, 1 1/2, 1 3/4, 2, 2 1/2, 3 1/2, and 4 1/2 in. Extruders have easy to clean, slide mounted roll for feeding rubber strips to extruder screw and ratio controlled drive system. Water-cooled feed sections are available in standard, tangential, and tapered lid styles. Instrumentation for process control is available.Original Press Release:

Wayne Machine Introduces New Rubber Extruder Product Line

Previously known for plastic and silicone extruders, Wayne introduces the new line of Yellow Jacket Rubber Extruders, designed and manufactured to meet the special challenges that are presented in the precision processing of rubber into extruded tubing, profiles, wire insulation, cable coating, sheet, film, rod, and many other extrusion applications. Standard screw sizes are 5/8", 3/4", 1", 1-1/4", 1-1/2", 1-3/4", 2", 2-1/2", 3-1/2" and 4-1/2". Wayne has incorporated many features to aid in the precision processing of rubber. The easy to clean, slide mounted roll feed has been designed to aid in the feeding of the rubber strips to the extruder screw and has its own ratio controlled drive system that is electronically linked to the extruder screw drive. Water cooled Feed sections are available in standard, tangential, and tapered lid styles and are easily changed for different rubber materials.

Electrically heated/Water cooled cast heaters are used on the barrel for easy maintenance and temperature stability. The closed loop water cooling system features microprocessor based controls, flow valves, recirculating pump with reservoir and a heat exchanger. Screws are available in many designs including constant depth variable pitch, Yellow Jacket Rubber Barrier Screws, and different pitch compression ratios depending on the material and the processing needs of the particular extrusion application. Shape Heads / Dies are supplied with split clamp or bolt on flange and a quick change hex head for easy die changes, or as crossheads for coating operations. AC Flux vector drives are utilized to maintain constant torque even at low speeds. A wide variety of optional instrumentation for process control is available. The pictured model is a 1-1/2" 12:1 L/D style, and the extruders are also available as table top models, vertical and co-extrusion satellite configurations.