Rotary Flex Testing on a Pipefitting Test Bench

Data acquisition systems have helped to increase quality control and cut costs in a wide range of manufacturing fields. One particular customer to discover this was a leading hydraulic tube and fitting manufacturer in India. Their company developed many different pipe-fitting systems and exported a full 90% of their products worldwide. With the use of a data acquisition system and its software monitoring a test bench, this company was able to optimize its rotary flex test procedures and guarantee a better product.

In order to ensure high product quality, it was necessary for the customer to perform both pressure and leakage tests on each production lot. The test engineers constantly performed a rotary flexure test of the hydraulic joints and fittings according to the ASTM F-1387 standard. The customer required a universal data acquisition system in order to monitor and automate this test bench application.

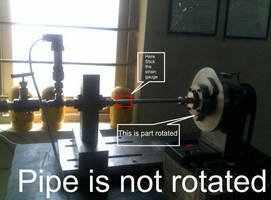

These tests were performed in a precise sequence: the hydraulic joints were first mounted to a 12mm-diameter tube which measured 6 inches long. This tube was then mounted to a support rest on one side and to a rotating spindle on the other side. The spindle was rotated at a speed of 1750 RPM. While the spindle was rotating, the pressure inside the tube was raised up to 25 BAR.

This test continued running for 10-15 minutes to measure the twisting forces of the tube and also to measure the pressure level. If the pressure started declining, the test engineer knew there were leakages on the fitting seal rings. The photo to the right shows the test bench setup:

For this test bench application, the CAS DataLoggers recommended and installed a Delphin Expert Key 100L USB/Ethernet Data Acquisition System in combination with Delphin's ProfiSignal Klicks software. ProfiSignal Klicks was installed on a workroom PC to enable data acquisition and test stand automation using either USB or Internet. The Expert Key system featured both analog and digital inputs and outputs in a compact unit inside a benchtop enclosure. Analog inputs support mV, volt, 20 mA signals, thermocouples, and RTD sensors. This high-speed system also had a maximum sample rate of 100 kHz with 18-bit measurement resolution.

The functional design is presented to the right:

In order to operate the test bench, the test engineer used a ProfiSignal Klicks application with the following user interface (main screen).

The engineer could specify the part number of the product currently undergoing testing. With the click of another button, he could then start the data logging and the test cycle. During the test, the live data consisting of speed (RPM), strain (torque), deflection and pressure were all displayed. When the test was finished, a report was automatically generated showing a strip chart of all test data, as well as a data table with all measurement values available.

The customer realized several convenient benefits after installing the Delphin Expert Key 100L system. The Expert Key had universal analog and digital inputs for measurement of ration speed (pulses) and analog signal (mA, V, mV, TC, RTD) simultaneously. Additionally, the ProfiSignal Klicks software was designed as a user-friendly development system for mimic building (HMI) and for programming the data recording and reporting functions--no specialized IT knowledge was required. Klicks also featured functions for automating processes. Finally, the Expert Key's USB interface made configuration and setup of the whole system quick and simple.

For further information on temperature monitoring solutions, cold chain logistics and transport applications, facilities monitoring and alarming, data acquisition and control, and data logging and remote monitoring applications, contact a CAS DataLogger Applications Specialist at (800) 956-4437 or visit the website at www.DataLoggerInc.com.

Contact Information:

CAS DataLoggers, Inc.

12628 Chillicothe Road

Chesterland, Ohio 44026

(440) 729-2570

(800) 956-4437

sales@dataloggerinc.com

www.DataLoggerInc.com