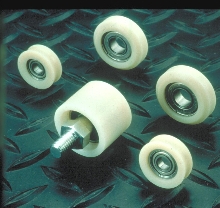

Rollers are custom made for each application.

Press Release Summary:

Power-Core rollers have composite tires installed over roller or needle bearings. Rollers are custom manufactured to meet specs derived by engineering analysis of load data. Calculations include Hertzian stress and linear speed that enable engineers to make design recommendations. Applications include clean room conveyors, linear positioners, sliding door hardware and automatic doors for motor vehicles, trains, incubators and storage systems.

Power-Core rollers have composite tires installed over roller or needle bearings. Rollers are custom manufactured to meet specs derived by engineering analysis of load data. Calculations include Hertzian stress and linear speed that enable engineers to make design recommendations. Applications include clean room conveyors, linear positioners, sliding door hardware and automatic doors for motor vehicles, trains, incubators and storage systems. Original Press Release:

Engineering Analysis Of Load Unlocks Key To Creating Long-Wearing, No-Flat Rollers With Exceptional Performance Properties

Closter, NJ: Operating on the principle that the life of a roller assembly depends as much upon its design as it does on the materials from which it is constructed, Intech Corporation replaces conventional, all-metallic roller assemblies with Intech Power-Core rollers.

Proprietary engineering analysis accurately calculates the optimum configuration of a roller for use within its particular application. Intech Power-Core rollers are then custom manufactured to meet the specifications derived from the engineering analysis of load data provided. Applications for Intech Power-Core rollers include clean room conveyors, ski lifts, high speed linear positioners, lifts for the disabled, high-quality sliding door hardware and automatic doors for hotels, aircraft, motor vehicles, trains, incubators and storage systems.

Intech Power-Core rollers feature composite tires installed over roller or needle bearings that are developed from a proprietary load calculation based upon size and life expectancy. The material's remarkable characteristics combined with proprietary calculations provide precision, efficiency, ease of movement, silence, longer component life and reduction of operating costs.

The exceptional thermal-fit, snap-in roller assembly of the composite tire over roller bearing outperforms conventional press-fit processes made from Delrin® or Nylon 6 material in high load and substantially higher temperature applications.

Custom manufactured to bear high loads, Intech Power-Core rollers naturally resist flat development, reduce shock and noise, and provide dimensional stability in moisture and extreme temperature environments. The composite material enhances dimensional stability, tensile strength and elasticity as it resists flat development by reducing material flow under load. In addition, the roller resists chemicals, cavitation, and abrasion from friction or fluids during operation or washdown. The gravity-cast roller material features a homogeneous crystalline structure that is characterized by easy-gliding, self-lubricating properties that impart rail protection to protect against premature wear.

Intech's proprietary roller calculations include Hertzian stress and linear speed that enable the experienced in-house engineers to make design recommendations to achieve optimum performance and cost savings.

Intech Power-Core rollers are offered in a variety of configurations, including flat, shouldered concave, convex, v-concave and crowned. Complete roller assemblies with shoulder bolts, eccentric bushings, axles and cam followers or other attachments are also available.