Right-Angle Spring-Loaded Connectors have .090 in. full stroke.

Press Release Summary:

Model 829-22-0XX-20-002101 connectors feature mid-stroke distance of .045 in. and are suited for hand-held devices. Units include tails bent at right-angles and locating pegs on insulator. Installed as through-hole components, they provide secure connection to PC board via hand, intrusive reflow, or wave soldering. Included spring-loaded pins are rated at 2 A continuous, 3 A maximum, while gold-plated brass components and beryllium copper springs maximize conductivity and corrosion resistance.

Original Press Release:

Mill-Max Adds a Long Stroke Option to Right-Angle Spring-Loaded Connectors

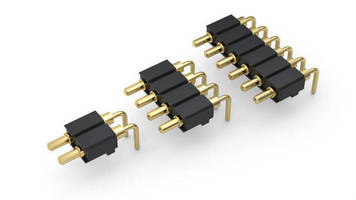

Mill-Max has added a second version to our 829 series single-row, right-angle, spring-loaded connectors. The new connector, 829-22-0XX-20-002101, has an increased mid-stroke distance of .045" (.090" full stroke) – close to double most standard series products and providing more flexibility and tolerance for your assembly.

Both versions of the 829 series are the perfect solution for applications calling for a spring-loaded connection that lies parallel to the PC board. Spring-loaded connectors (SLC) are commonly used to provide a high quality battery interface connection and in applications such as board-to-board interconnects and blind mate assemblies. These low profile, right angle connectors are ideal for the small packaging requirements of hand-held devices, especially where vertical space is limited.

With tails bent at right-angles and locating pegs on the insulator, the 829 series connectors are installed as through-hole components providing a secure connection to the PC board. These SLC’s are suitable for hand, intrusive reflow or wave soldering.

Gold-plated brass components and beryllium copper springs ensure the highest conductivity, corrosion resistance and durability. The 829 series connectors feature spring-loaded pins rated at 2 amps continuous (3 amps maximum), use high temperature Nylon 46 insulators and are offered in up to 20 positions in a strip.

For more information, please visit: www.mill-max.com/PR639.

Mill-Max is the leading US manufacturer of machined interconnect components with a vertically integrated manufacturing facility headquartered at 190 Pine Hollow Rd., Oyster Bay, NY 11771. Its full product line includes spring-loaded connectors, SIP, DIP, PGA and BGA sockets, board-to-board interconnects and pin headers, surface mount and custom products, PCB pins and receptacles, solder terminals, wrapost receptacles and terminals. The company’s complete manufacturing facility includes engineering, tooling, primary and secondary machining, stamping, plating, injection molding, and assembly.

For more information, contact Robin D. Ritter, Marketing Coordinator, Mill-Max Mfg. Corp.,

Tel: 516-922-6000 ext. 211; Fax: 516-922-9253;

Email: rritter@mill-max.com; www.mill-max.com; PR639.