Remote Monitoring Software improves laser cutter uptime.

Share:

Press Release Summary:

MC Remote 360 increases productivity, improves efficiency, and reduces downtime for MC Remote 360-enabled machines. Compatible with PCs and mobile devices, machine-monitoring module offers real-time access to header as well as machine state/status and production performance data. Solution also offers access to machine backup files via cloud, user alerts and notifications, and maintenance monitoring. Real-time remote diagnostics, fault monitoring, and support are also standard.

Original Press Release:

MC Machinery Systems Introduces MC Remote 360

Technology makes it possible to monitor the laser-cutting process from desktop and mobile

Wood Dale, IL — MC Machinery Systems, a subsidiary of Mitsubishi Corp, introduces a new software solution to provide production monitoring, support and transparency to the laser-cutting process. MC Remote 360 provides owners and operators with real-time data to increase productivity, improve efficiency and reduce downtime for MC Remote 360-enabled machines.

Current machines supporting MC Remote 360 are the NX Series, NX-F Series, RX Series, eX Series and XL Series. Machines that will support the system soon include the LVPlus Series (with Windows XP) and the LVPlusII Series.

“We are continually trying to raise the level of customer satisfaction and the launch of MC Remote 360 is directly in line with that goal, says Vice President of Service Tony Imbrogno. “Access to information is key and it will offer an elevated service experience to our customers. This new technology took nearly two years to develop and with beta testing complete, we are excited to officially offer this product- and hope to eventually offer it on every machine we sell.”

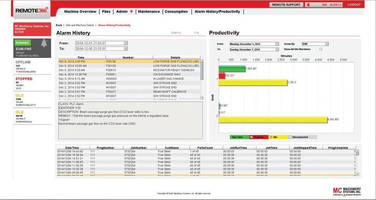

The machine-monitoring module provides the ability to monitor MC Remote 360-enabled machines from a PC or mobile device. Various aspects of the machine, such as run, stop and idle time, are tracked and analyzed to provide insight on potential process improvements.

This new monitoring system has many exciting features—including real-time access to an extensive amount of data about machine state, machine status and production performance, as well as a view of the program header. Plus, MC Remote 360 includes access to machine backup files via the cloud, user alerts and notifications, and maintenance monitoring.

MC Machinery Systems Remote Diagnostics & Fault Monitoring provides real-time support and troubleshooting if issues arise with a machine. The system notifies an MC Machinery support staff member in the event of a problem, who will help the machine owner troubleshoot the issue via remote machine feedback, or schedule an onsite visit.

In addition, Remote Support Service allows issues to be diagnosed and resolved while using the remote support module, potentially eliminating the need for an onsite visit. With the press of a button, the operator can grant MC Machinery technicians the ability to view all of the screens, change parameters, or upload/download program and material files.

About MC Machinery Systems

MC Machinery System’s superior products are backed by industry-leading service and support. For more information about Wire EDM, Sinker EDM, Additive Manufacturing, Laser, Waterjet, Press Brake, Milling, High-Speed VMC, EDM Drill, or Consumable Products, contact MC Machinery Systems, Inc., 1500 Michael Drive, Wood Dale, IL 60191, Phone: 630-616-5920 or visit www.mcmachinery.com.