Semiconductor Processing Equipment

Reader tracks semiconductor wafers through manufacturing.

Press Release Summary:

Featuring image formation technology and OCR, 2D matrix, and barcode recognition algorithms, In-Sight® 1721 delivers reliable reading performance on SEMI-standard scribes. It can read wafer marks that have been affected by CMP, edge beads, copper metallization, and blue or green nitride coating. GUI facilitates set up, and automatic tuning minimizes operator intervention. Built-in network and serial communications provide connectivity to other process tools and fab network.

Original Press Release:

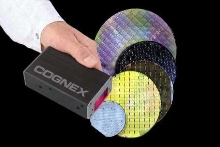

Cognex Introduces Next-Generation Wafer Reader

In-Sight 1721 reader sets new performance standard

Natick, MA, July 12, 2005-Cognex Corporation (NASDAQ - CGNX), the world's leading supplier of machine vision systems to the semiconductor industry, today announced that it has expanded its family of wafer ID readers to include the In-Sight® 1721. Used for tracking semiconductor wafers through the manufacturing process, the In-Sight 1721 offers a slimmer package and twice the speed of its predecessors, yet maintains mounting and functional compatibility with them.

"As fabs move toward full wafer traceability, they are more dependent than ever on reliable automated wafer identification," said Justin Testa, Senior VP of ID Products for Cognex. "The In-Sight 1721, the newest member of Cognex's series of industry-leading wafer readers, reads faster with higher yield under difficult real world process conditions."

Advanced image formation technology and industry-leading OCR, 2D matrix, and barcode recognition algorithms enable the In-Sight 1721 to deliver reliable reading performance on SEMI-standard scribes. The 1721 also provides exceptionally high read rates on wafer marks that have been affected by CMP, edge beads, copper metallization, blue or green nitride coating, and other process effects.

The In-Sight 1721 offers flexible mounting options for easy installation on wafer sorters, ion implanters, probers and other tools. A graphical user interface simplifies set up, and automatic tuning minimizes operator intervention. Built-in network and serial communications provide connectivity to other process tools and the fab network.

The In-Sight 1721 will be available in September.

About Cognex

Cognex Corporation designs, develops, manufactures, and markets machine vision systems, or computers that can "see." Cognex is the world's leader in the machine vision industry, having shipped more than 250,000 machine vision systems, representing over $1.8 billion in cumulative revenue, since the company's founding in 1981. Cognex's Modular Vision Systems Division, headquartered in Natick, Massachusetts, specializes in machine vision systems which are used for automating the manufacture of a wide range of discrete items and for assuring their quality. Cognex's Surface Inspection Systems Division, headquartered in Alameda, California, specializes in machine vision systems which are used for inspecting the surfaces of products manufactured in a continuous fashion, such as metals, papers, and plastics. In addition to its corporate headquarters in Natick, Massachusetts, Cognex also has regional offices and distributors located throughout North America, Japan, Europe, and Southeast Asia. Visit Cognex on-line at www.cognex.com.