Punch Laser Machine provides scratch-free processing.

Press Release Summary:

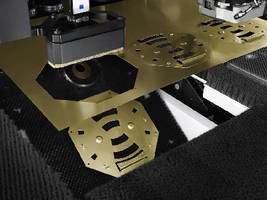

Combining high speed solid-state laser processing with punching and forming technology, TruMatic 6000 fiber rapidly laser cuts, punches, forms, and engraves sheet metal up to 0.25 in. thick. Solid-state laser enables system to process non-ferrous metals, such as copper and brass, in addition to mild steel, stainless steel, and aluminum. TruDisk laser resonator increases process reliability since laser is impervious to back-reflections, and can be configured to share laser as part of Laser Network.

Original Press Release:

Combination Punch Laser Processing

FARMINGTON, Conn., – TRUMPF’s TruMatic 6000 fiber punch laser combination machine unites the advantages of high speed solid-state laser processing with high quality punching and forming technology. This newly introduced machine rapidly laser cuts, punches, forms and engraves sheet metal up to 0.25 inches thick while setting new standards in productivity and process reliability. The machine is designed for scratch-free processing while an intuitive laser output control system ensures superior quality when cutting delicate curves and tight radii

The productivity of the solid-state laser is most evident in galvanized mild steel and stainless steel. When cutting these materials processing speeds are up to six times greater than with a CO2 laser of the same power, and the cut quality is excellent. The efficient solid-state laser enables the the TruMatic 6000 fiber to now process non-ferrous metals, such as copper and brass, in addition to mild steel, stainless steel and aluminum. The unique design of the TruDisk laser resonator not only increases process reliability since the laser is impervious to back-reflections, it can also be configured to share its laser as part of a Laser Network to support additional laser processing operations, such as laser welding.

Automation at every step

TRUMPF has developed solutions for the TruMatic 6000 fiber, such as automation to enhance material flow and tool changes and smart machine functions, to minimize non-productive time. The smart punch monitoring function determines whether a punch has broken and will stop the machine and notify the operator in the event of an issue. The smart load function automatically and precisely aligns the sheet on the machine while the smart unload function optimizes the removal process. The machine is also able to recognize if a part is stuck in skeleton, if it cannot be removed automatically, the machine will stop to avoid collision. Finished parts are then deposited into carts by way of a fast-action parts chute or they can be sorted and positioned in carts or on pallets with help from the SheetMaster’s individually controlled vacuum grippers. Tool changeover takes place very quickly due to the linear magazine, which can store up to 23 tools depending on the number of clamps used in production. When a greater number of tools are required the SheetMaster can be augmented with a tool changer providing storage for 40 additional tool stations. As an alternative, the ToolMaster can store and exchange 40 to 70 tools. With these developments, the TruMatic 6000 fiber carries out operations automatically while minimizing the non-productive time of the machine.

Unmatched accessibility and productivity

TRUMPF designed the TruMatic 6000 fiber with unique quick-access entrance points so that all critical areas are easily reached despite the protective housing required for cutting with the solid-state laser. As a result, tool setup, punch inspection and material changes can occur very quickly when operating either the stand-alone or the automatic version of the machine. The standalone version also features large sliding doors which make it possible to unload sheets below the machine’s table. Since the enclosure is only required when the laser is processing, the doors may remain open during punching operations and when the laser is active, the enclosure’s large viewing windows provide operators with maximum visibility of the work area. The TruMatic 6000 fiber has been designed with the highest regard for laser safety yet still provides operators with maximum accessibility to facilitate higher productivity whether laser cutting, forming parts, loading or unloading the machine.

About TRUMPF

TRUMPF is the world market and technology leader in fabricating machinery and industrial lasers for flexible sheet metal processing. Products manufactured with the company's technology can be found in almost every sector of industry. TRUMPF Inc. is the largest subsidiary of the TRUMPF Group and is dedicated to serving the U.S., Canadian and Mexican markets. Additional company information is available at: www.us.trumpf.com

Press contact:

Susan Groh

Public Relations & Media Representative

860-255-6104

Susan.Grohs@us.TRUMPF.com