Pulley Lagging eliminates conveyor belt slippage.

Press Release Summary:

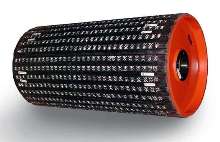

Suited for abrasive or highly wet or dry applications, Ceramic Pulley Lagging is made from hundreds of individual ceramic tiles molded into rubber backing. It provides drive traction, minimizes wear from abrasive materials, and extends life of key conveyor components as it eliminates need to over-tension belt. Self-cleaning action prevents material buildup. Lagging can be attached to pulley via vulcanizing, or can be bolted or welded to face of pulley.

Suited for abrasive or highly wet or dry applications, Ceramic Pulley Lagging is made from hundreds of individual ceramic tiles molded into rubber backing. It provides drive traction, minimizes wear from abrasive materials, and extends life of key conveyor components as it eliminates need to over-tension belt. Self-cleaning action prevents material buildup. Lagging can be attached to pulley via vulcanizing, or can be bolted or welded to face of pulley.Original Press Release:

Superior Industries' New Ceramic Pulley Lagging Increases Drive Traction & Eliminates Slippage

MORRIS, MN. - Leading conveyor systems and components manufacturer, Superior Industries, features ceramic pulley lagging as an ideal solution for producers who wish to boost productivity by eliminating costly belt slippage problems. Particularly suited to abrasive or highly wet or dry applications, Superior's ceramic lagging provides significantly greater traction than conventional lagging. Constructed from hundreds of individual ceramic tiles molded into a durable rubber backing, ceramic lagging cuts maintenance costs, reduces wear from abrasive materials, and extends the life of key conveyor components as it eliminates the need to over-tension the belt to attain greater traction.

Delivering complete in-house lagging capabilities, Superior stresses proper pulley lagging as an integral part of efficient and economical conveyor operation no matter what the application. Proper lagging reduces load and wear on the drive, belt, pulleys, bearings, and take-up, while also creating a self-cleaning action that prevents material buildup. In addition to ceramic lagging, Superior also offers vulcanized rubber and Holz lagging options. For long life and high traction, 60-durometer lagging is standard, with other lagging durometers available. Lagging can be attached to the pulley via vulcanizing, or can be bolted or welded to the face of the pulley.

Superior Industries offers a comprehensive line of components, equipment, and systems for sand gravel, aggregate, mining, concrete, asphalt, recycling, civil and marine engineering, wood, pulp, and paper, chemical processing, electric utility, coal, grain, and other processing industries.

For more information, contact Garrett Ashburn at Superior Industries, P.O. Box 684, Morris, MN 56267. Phone: 320-589-2406; Fax: 320-589-2260; Email: marketing@superior-ind.com. Or visit www.superior-ind.com.