Progressing Cavity Pumps work in many applications.

Press Release Summary:

Model 2000 pumps are available in variety of construction materials to handle applications from shear-sensitive liquids to process slurries and sludges. Options include: Flush Gland that allows packing leakage to be flushed away from pump, preventing damage to seals and packing; Fiber Deflector, which prevents ragging around rotating shafts when stringy materials are present; and Shaft Sleeve, which protects drive shaft from wear in highly abrasive applications.

Model 2000 pumps are available in variety of construction materials to handle applications from shear-sensitive liquids to process slurries and sludges. Options include: Flush Gland that allows packing leakage to be flushed away from pump, preventing damage to seals and packing; Fiber Deflector, which prevents ragging around rotating shafts when stringy materials are present; and Shaft Sleeve, which protects drive shaft from wear in highly abrasive applications.Original Press Release:

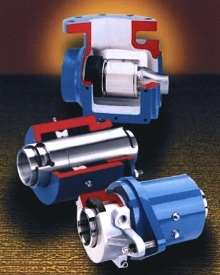

Moyno® 2000 Progressing Cavity Pumps Offer Options To Suit Most Applications

Springfield, Ohio, USA - Moyno, Inc. offers the Moyno® 2000 Progressing Cavity Pump, a versatile, high-performance pump designed to handle a wide range of applications from shear-sensitive liquids to difficult-to-process slurries and sludges.

Moyno 2000 Pumps are available in a variety of construction materials with many different performance-enhancing options, allowing customization to specific needs. Some of these options include the following:

- Flush Gland -- allows packing leakage to be flushed away from the pump, preventing potential damage to seals and packing

- Fiber Deflector -- prevents ragging around rotating shafts when stringy materials are present in the fluid being pumped

- Shaft Sleeve -- protects drive shaft from wear in highly abrasive applications

Moyno, Inc. is a leading manufacturer and marketer of Moyno progressing cavity pumps and systems. The Company has operations in the U.S., the U.K., Singapore and Mexico, and an extensive worldwide stocking distribution network. The Company serves a wide range of industries including water and wastewater treatment, pulp and paper, chemical, food, pharmaceutical, mining, petrochemical and oil and gas recovery. Moyno, Inc. is a unit of Robbins & Myers, Inc.