Plate Style Filter eliminates dust in plasma cutting.

Share:

Press Release Summary:

As plate filter with special coating that cleanses air of ultra-fine dust particles, PlasmaFIL eliminates need for regular overhauls. Due to flow of untreated air in top of filter system with down-flow principle, filter is designed like plate and not cylinder. Individual pleats in filter do not move on top of each other, preventing them from sticking together and optimizing media utilization. Also included, integrated spark pre-separator prevents filter fires and reduces strain on filter.

Original Press Release:

KEMPER Brings Durable Filter Technology on the Market with the New PlasmaFIL

•Â Service life of the innovative filters nearly unlimited

• Especially designed for plasma cutting machines

• voestalpine already convinced at the market launch

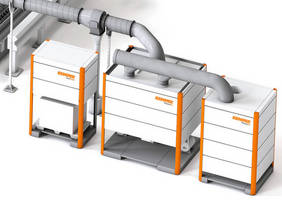

Vreden – Thanks to innovative filter technology with increased efficiency in air pollution control: With PlasmaFIL, KEMPER GmbH presents a solution with an extremely long useful life and filter service life. The system is particularly suitable for the elimination of large quantities of dust specifically in plasma cutting. Thanks to its special design, regular overhauls of the filter are not necessary. From the moment it came on the market, the manufacturer already recorded its first sales success.

“With our new product, PlasmaFIL, we are closing a very important gap in the market”, says Managing Director, Bjorn Kemper. “Thanks to its special way of functioning, the useful life of the filter cartridge is extended significantly.” Regular filter changes are no longer required. Service lifetimes are nearly unlimited.

Newly developed plate filter, a central element

The core of the new system is an innovative plate filter with a special coating, which also cleanses the air of ultra-fine dust particles. Due to the flow of untreated air in the top of the filter system with the down-flow principle, the filter was designed like a plate and not like a cylinder, as was previously the case. This has the following advantage: Contrary to the round filter cartridge design, the individual pleats in the filter do not move on top of each other, which prevents them from sticking together. In this way, the entire surface of the filter is used in the filtering process.

“Due to the possibility of filtering large amounts of dust with PlasmaFIL, the new filter system was developed specifically for use in plasma cutting machines”, emphasizes Kemper. The integrated spark pre-separator, SparkTRAP, also contributes here. Through the pre-separation of coarse dust particles and sparks, it prevents filter fires and reduces the level of strain on the filter. Positive side effect: Energy consumption of the filter system is considerably reduced and the service life of the filter is extended.

Contamination-free dust removal

Compared with conventional filter systems, PlasmaFIL does not even use a dust container. With DustEVAC, KEMPER relies on a vacuum-based disposal for the PlasmaFIL. The dust is collected in a high capacity BigBag. This enables contamination-free disposal and can, contrary to conventional containers, be changed during the cutting process without having to interrupt the work.

With the installation of a separate, silenced ventilator, the noise pollution can also be kept at a low level. Users operate and monitor the system via a central touch screen. It is even possible to communicate with the plant engineering department or to integrate it into the software of connected equipment. A start-stop function is integrated as a standard feature.

voestalpine subsidiary relies on filter design

The feedback on the new KEMPER product could not be any better: From the moment it came on the market, the equipment manufacturer already recorded its first sales success of the high-end extraction solution. “This innovative filter concept has convinced us with its very high service lifetimes”, says Walter Radinger, Process Manager of Cut Shapes at the Austrian company voestalpine Anarbeitung GmbH, a full subsidiary of the publicly-listed company, voestalpine AG. At the moment, there is no other comparable plate filter solution on the market. “We anticipate that with the help of this new system, we can considerably reduce the otherwise usual operating costs of our filter systems.”

The metal-processing company can even use the new filter system completely without having to purchase it, thanks to the new sales concept at KEMPER. Instead of purchasing the systems, interested parties may also rent them from the manufacturer. In conjunction with the filter’s service life guarantee and full service contracts, consequential costs remain low and can be accurately calculated.

Further Informationen under: www.kemper.eu

About KEMPER GmbH:

Kemper GmbH is a medium-sized family enterprise based in the town of Vreden in North Rhine-Westphalia. The company’s product categories include the areas of extraction and filter technology as well as storage and automation technology. This also includes, among others, highly efficient filter systems, which also filter ultra-fine dust particles from the air, extraction tables for cutting processes and a complete accessory line with regards to work safety and air pollution control for the metal-processing as well as the electrical and automotive industry. The manufacturer also makes sheet metal, long component as well as pallet and container storage systems as well as automation systems for loading and unloading, equipped with corresponding control and warehouse management software. KEMPER is the world market leader in the area of extraction and filter systems for the metal-processing industry. The company was established in 1977 and currently employs around 300 people. Next to its head-quarters in Vreden, KEMPER also has production facilities in Lünen as well as in Shanghai (China) and Prague (Czech Republic). The company is globally represented with more than eight branches and numerous trading partners.