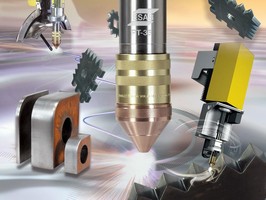

Plasma / Flame / Laser Cutters and Cutting Machinery

Plasma System combines cutting and marking in single system.

Press Release Summary:

With single plasma torch, ESAB m3 Plasma System produces high-speed standard plasma cutting, precision cutting and marking, and high-current, thick-plate cutting. PT-36 torch produces cut face with low dross, requiring little secondary clean up, and can function in both dry and water injection modes. When configured for 600 A operation, system can cut and mark material from 20 Ga to 6.25 in. without sacrificing cut quality.

Original Press Release:

New ESAB m3 Plasma System Combines High Speed and High Precision Plasma Cutting in a Single System

Florence, SC - ESAB's new m3 Plasma System combines multiple plasma cutting and marking features in a single easy-to-use system, taking plasma cutting productivity to new heights. The m3 system produces high-speed, low-cost standard plasma cutting; high-quality precision cutting and marking; and high-current, thick-plate cutting all with a single plasma torch. When configured for 600 amp operation, the system can quickly and accurately cut and mark material from 20 ga. to 6.25 inches (1mm to 160mm) without sacrificing cut quality.

The key to this new system is the new state-of-the-art PT-36 torch design. Instead of setting a fixed cutting current and adjusting other parameters to achieve the desired cutting result, ESAB starts with the desired result and then determines the best parameter settings, including current, needed to achieve it. This design allows ESAB to achieve superior cutting and marking results over a wide range of materials and thicknesses while using the fewest consumable parts in the industry. The new PT-36 torch replaces up to three single-purpose torches (heavy plate cutting, precision cutting and marking) and produces a superior cut face with low dross, requiring little secondary clean up. The end result is superior cutting functionality and productivity, with minimal set-up time, downtime and consumable cost. The new torch can function in both dry and water injection modes.

The m3 system features the most advanced gas control system in the industry, fully automated by ESAB's Vision CNC. Great flexibility in selection and mix of shield gases allows an operator to produce the best cut quality on any material. The operator simply selects the material type and thickness, and the Vision CNC automatically selects and mixes the optimal start, cut and shield gas combination. Process parameters for most plasma cutting and marking applications are preloaded in the Vision CNC, and custom parameter files can be easily created as needed.

ESAB Welding & Cutting Products is one of the world's largest and most experienced manufacturers of welding and cutting equipment and welding filler metals. Recognized as the technological leader in the industry, ESAB is committed to providing customized solutions for its customers. For more information on the m3 plasma system, visit www.esabna.com or call 1-800-ESAB-123.

FOR MORE INFORMATION, CONTACT:

Debi Ratliffe

ESAB Welding & Cutting Products

843-679-6317

dratliffe@esab.com