Multi Axis Positioning Stages / Tables

PI Introduces Miniature Hexapod Features Removable Magnetic Kinematic Plate

Press Release Summary:

PI’s H-811.F2 Miniature Hexapod is available in various sizes with base sizes ranging from 50mm to 1m. Unit offers 6 DOF, 5 nm actuator resolutions and 60 nm repeatability. Designed for industrial precision alignment applications, unit comes with low friction ballscrews, joints, user programmable pivot point and a controller with build-in multi-axis alignment routines. The hexapod provides travels up to 34 mm for linear motions and up to 42° for rotary motions with a velocity up to 20 mm/sec.

Original Press Release:

New Miniature Hexapod for Photonics Alignment provides Dynamics and Precision, and Automated Alignment Algorithms

Engineered by PI for high duty cycle applications, this new hexapod comes with a removable magnetic plate for fiber optic component holders and adapters.

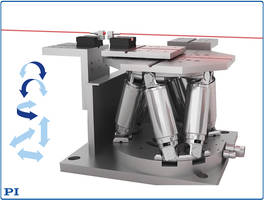

May 2018, Auburn, MA – PI has added a high dynamics model to its range of compact hexapods. Designed for photonics alignment applications, the hexapod provides 6 degrees of freedom, actuator resolution of 5 nanometers and repeatability as good as 60 nanometers, while providing velocities to 20mm/sec. Sustaining loads to 5kg, the new H-811.F2 features a removable magnetic kinematic plate to accelerate workflow with different fiber optics components. Its compact size, large travel range of up to 34mm for linear motions and up to 42° for rotary motions, and a user programmable pivot point facilitate work with fiber optic and photonics components.

High Duty Cycle – Design for Industrial Alignment

The hexapod is designed for industrial precision alignment applications with long-life brushless motors and low friction ballscrews and joints. A powerful controller with build-in multi-axis alignment routines makes the new hexapod an ideal tool for automatic alignment tasks.

How do Hexapod Parallel Motion Systems work?

Hexapods are 6 DOF positioning / motion systems that derive 6-axis movement (XYZ, pitch, yaw, roll) from actuators placed in parallel between a top and bottom platform. Available in a variety of sizes with bases ranging from 50mm to 1m and different load capabilities up to 2 tons, PI hexapods are an easy solution to complex multi-axis precision motion applications. PI hexapods come with state-of-the-art controllers and software tools based on 25 years of hexapod R&D, resulting in fast solution implementation to a plethora of applications from medical to photonics. All 6 axes can be commanded simply as Cartesian coordinates, and the center of rotation can be changed on the fly with a software command. Other advantages are the absence of friction and torque, caused by dragged cables.

Read technical articles and applications of PI hexapods> http://www.pi-usa.us/blog/category/photonics/

Watch hexapod video> https://www.youtube.com/embed/RUUdTI68Kt4?rel=0

Features & Advantages

- 6-Axis system (XYZ, Theta X, Y, Z)

- Travel ranges to 34mm linear / 42° rotary

- Strut resolution: 5 nanometers

- Load capacity to 10lbs

- Repeatability to 0.06µm

- Velocity to 20 mm/sec

Specifications, Datasheets, More Information > http://www.pi-usa.us/products/Photonics_Alignment_Solutions/index.php#H-811

Standard and Custom

PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application.

USA / Canada

http://www.pi-usa.us | info@pi-usa.us

East

(508) 832-3456

Midwest

(508) 832-3456

West

(949) 679-9191 (LA Area & Mexico)

(408) 533-0973 (Silicon Valley/Bay Area)

About PI

PI is a leading manufacturer of air bearing stages, piezoelectric solutions, precision motion control equipment, and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. The PI group employs more than 1,000 people worldwide in 15 subsidiaries and R&D / engineering centers on 3 continents.