Phased Array Probe simplifies corrosion inspection.

Share:

Press Release Summary:

Promoting productivity via 1.26 in. beam coverage width, scan speed, and C-scan imaging with optimized data-point density, Dual Linear Array™ probe uses pitch-catch technique that increases quality of near-surface resolution and pit detection in corrosion survey applications. Features include 0.4 in. near-surface detection capability, quick adjustment system that adapts to diameters from 4 in. to flat, and carbide wear plates for wedge protection. Product comes in aluminum housing.

Original Press Release:

A New Dual Linear Array Probe for Fast, Simple, and Reliable Corrosion Imaging

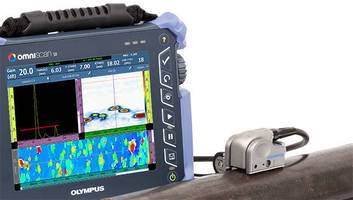

The new Dual Linear Array™ probe for corrosion inspection provides several advantages over conventional ultrasonic dual element transducers used with flaw detectors. This phased array solution improves productivity through features such as larger beam coverage, faster scan speed, and C-scan imaging with increased data-point density. The pitch-catch technique used by this new probe can offer better near-surface resolution and pit detection in corrosion survey applications than standard phased array pulse-echo, improving probability of detection of critical wall thinning. The Dual Linear Array probe adds a new low-cost entry-level inspection capability to the existing Olympus HydroFORM® and RexoFORM corrosion solutions, especially when combined with the OmniScan® SX.

Probe Features

Near-surface detection capability of 1 mm (0.4 in.).

Beam coverage width of up to 32 mm (1.26 in.).

Quick adjustment system adapts to diameters from 4 in. to flat.

Carbide wear plates for wedge protection.

Lightweight aluminum housing.

Ready for encoded data acquisition.

OmniScan configuration files (MX, MX2, and SX) on USB key.

This new probe is yet another product in Olympus’s complete offerings for corrosion inspection solutions utilizing ultrasound, phased array, eddy current, and remote visual inspection.