Pellet Screener handles capacities up to 1,500 PPH.

Press Release Summary:

Plastic Pellet Screener utilizes horizontal, gyratory/reciprocating motion and Dual Velocity drive with positive displacement stroke. Final product can be up to 99 percent free of longs 3/8 to 2 in. Vibration is minimized via its counter-weight drive. Plastic Pellet Screener includes mounting options such as casters, kick-down legs, or stand. Variable frequency tappers can be added for additional control of screen blinding without mesh cleaning balls.

Plastic Pellet Screener utilizes horizontal, gyratory/reciprocating motion and Dual Velocity drive with positive displacement stroke. Final product can be up to 99 percent free of longs 3/8 to 2 in. Vibration is minimized via its counter-weight drive. Plastic Pellet Screener includes mounting options such as casters, kick-down legs, or stand. Variable frequency tappers can be added for additional control of screen blinding without mesh cleaning balls.Original Press Release:

New Rotex(R) Pellet Screener Provides Unequalled Removal Of Off-Size Material

NEW ROTEX® PELLET SCREENER PROVIDES

UNEQUALLED REMOVAL OF OFF-SIZE MATERIAL

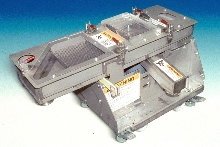

CINCINNATI, OH (November 15. 2001) - The new competitively-priced, high efficiency ROTEX® Plastic Pellet Screener is the ideal solution for compounders who need extremely accurate removal of off-size material.

This screener, first in a new line of pellet screeners from ROTEX, utilizes a unique horizontal, gyratory/reciprocating motion, and an exclusive patent-pending "Dual Velocity" drive with a positive displacement stroke to achieve unmatched removal of oversize and longs.

The long stroke, gyratory motion -four times as long as vibratory screeners- spreads pellets evenly across the full width of the unit. The motion then stratifies the material for exceptionally efficient fines removal and separation of the oversize from the on-spec pellets. Good pellets are not removed with the oversize.

The ROTEX motion contains no vertical component, so long pellets, "toothpicks" and "jackstraws" remain flat on the screen deck. They cannot upend or pass through the screen with the on-spec pellets, as they often do with vibratory screeners. For increased accuracy. a double pass option is available to screen pellets twice. Final product can be up to 99 percent free of longs 3/8" to 2" (0.9 to 5 cm).

The reliable, low-maintenance "Dual Velocity" drive operates at lower speeds, reducing noise and wear on components, and minimizes vibration with a counter-weight drive.

The ROTEX Plastic Pellet Screener is easily disassembled and reassembled for regular maintenance or for cleaning between batches, and is portable and simple to move off-line.

With its compact footprint and lower silhouette than most other screening machines, the ROTEX Plastic Pellet Screener has an installed height as low as 27" (69 cm). Mounting options include casters, kick-down legs or a stand.

When running longer batches without interruption for cleaning, unique variable frequency tappers can be added for additional control of screen blinding without the use of mesh cleaning balls. Optional stainless steel wire screens, perforated plates or a combination of the two can be installed to meet any separation requirement.

The ROTEX Plastic Pellet Screener is designed to handle capacities of up to 1,500 PPH. ROTEX also offers a wide range of pellet screeners for higher capacity screening up to 30,000 PPH with the same gyratory/reciprocating motion, accurate separation, compact design and installation configurations, and easy cleaning.