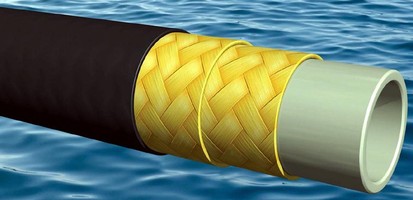

PEEK-Infused Hoses are designed for offshore operations.

Press Release Summary:

Optimized for chemical, thermal, and permeation resistance, PEEKline(TM) hoses incorporate liner tubes made from VICTREX® PEEK(TM) polymer and meet requirements of oil and gas offshore industry. Product has continuous-use temperature rating of 500ºF.

Original Press Release:

Introducing the Next Generation of High Performance Offshore Hoses

Thornton Cleveleys, UK - (May 5, 2008) - Kutting Ltd., the leading independent manufacturer of fully compliant hoses for the offshore industry, has unveiled a new range of PEEKline(TM) hoses designed with VICTREX® PEEK(TM) polymer. Kutting's new range of hoses incorporate liner tubes made from VICTREX PEEK polymer, in a proprietary design that takes advantage of the polymer's high mechanical properties, maximizes chemical, thermal and permeation resistance and meets the strictest requirements of the oil and gas offshore industry.

"Kutting is pleased to bring forth its PEEKline hose range to the oil and gas market through our successful application development program with Victrex," said Kevin Johnson, General Manager of Kutting. "We have set out to increase overall product performance and long-term reliability. With the use of VICTREX PEEK polymer in the hose lining, our product offers substantially improved permeation resistance, has higher chemical resistance and significantly improved temperature resistance compared to existing products in the market. This, in turn, allows umbilicals built with PEEKline hoses to perform in more demanding environments."

The permeability of VICTREX PEEK polymer to hot gasses and liquids, including hot methanol, is an estimated 100 times lower than existing polymer hose materials and has a 260°C (500ºF) continuous use temperature.

"As oil and gas exploration and production companies around the world face increasingly challenging conditions such as deeper water, more corrosive environments, and higher pressures and temperatures, the reliability of subsea equipment has become paramount," said Robert Navo, Global Applications Manager for Oil and Gas at Victrex. "As a result, Victrex has worked closely with Kutting to support the development of its new PEEKline hose range. VICTREX PEEK polymer successfully addresses Kutting's key areas of concern such as improved mechanical performance and chemical resistance."

Kutting supplies hoses for offshore applications including subsea umbilicals. Umbilicals take many forms and may contain electrical cables and hoses of different types, sizes and pressure ratings, including high collapse resistant (HCR) lines for chemical injection. Umbilicals can be static or dynamic or a combination of both and lengths may vary from short, in the case of hydraulic flying leads (HFL), to the long, in the case of production control umbilicals.

As the energy industry moves to more aggressive and demanding operating environments, technology is playing a significant role in the drive to reduce the overall cost of hydrocarbon recovery and develop alternative energy. The selection of the correct material is often seen as a key component for success when seeking to overcome these challenges.

Navo added, "VICTREX PEEK polymer is being specified more and more for oil and gas applications to help improve operating performance and reduce the risk of downtime associated with component failure. Victrex works with leading companies, such as Kutting, to develop new technologies to meet the ever-changing needs of the energy market."

Victrex USA, Inc., a division of Victrex plc, is the sole manufacturer and supplier of VICTREX PEEK polymer worldwide. For more information, please call (800) VICTREX or visit the Victrex website at www.victrex.com or victrex.mobi.

Kris Jommersbach

Gemini Communications

6 Beard Circle

Phoenixville, PA 19460

PH: 610-935-1633

E: krisj@geminiinc.com