PCB Solder Pad accommodates 2 different LED types.

Press Release Summary:

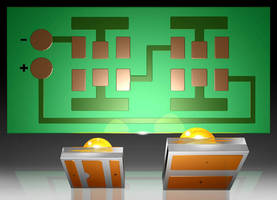

Board solder pad enables 2 different LED types, from different manufacturers, to be incorporated on same PCB. Individual solder surfaces are divided into electrically connected and electrically disconnected segments and, by selecting appropriate spacings between solder surfaces, second LED, rotated 90°, can be attached. By dividing solder surfaces, both LED types automatically align to solder surface edges during reflow process. Pad can be used for metal core, FR4, and ceramic boards.

Original Press Release:

New Solder Pad Design Enables Two Different LED Types to Be Accommodated on One Board

Oslon LEDs from Osram Opto Semiconductors offer uniform solder pad design to facilitate second sourcing

LEDs are not all the same. This is true of not only their performance and dimensions but also their solder pads and processing options. Osram Opto Semiconductors has now developed a concept for uniform solder pads based on the Oslon LED family, making it easier for customers to use LEDs from different manufacturers (second source) and reducing the costs of storage and process modification.

Second source is the term given to the ability to use different suppliers' products in a particular project or a series of products. Second sourcing is a standard practice for LED components because of the need for security of supply. Ideally, it should be possible to incorporate second sourced products into current production without incurring additional costs. However, components from different manufacturers generally differ in terms of their dimensions and shape of their solder pads. As a result, typically two different soldering boards are needed for the LEDs from two different manufacturers. This drives up costs for procuring and storing the boards and also for modifying the process to fit each board.

Now - only one adjustment to the board layout is required

Osram Opto Semiconductors has developed a concept for ceramic LED components, such as the Oslon family, that makes the board solder pad design so adaptable that it can be used for LED components from at least two different manufacturers. The concept can also be used for metal core, FR4 and ceramic boards.

"Only a small adjustment to the process is needed, and the benefits are real and long-term," according to Dr. Christian Gartner, Oslon Project Manager in Product Development General Lighting at Osram Opto Semiconductors. The combined board design comes from the design of one of the two LED components. The individual solder surfaces are divided into segments - electrically connected and electrically disconnected. By selecting appropriate spacings between the solder surfaces, the second LED product - rotated 90° - can be attached to the uniform board design. The anode and cathode of the two LED components are connected to the same electrically contacted segments. By dividing the solder surfaces the two LED types automatically align themselves to the edges of the solder surfaces during the reflow solder process. For both LED components, the luminous area is in the same lateral position on the board - in other words, in the same alignment in the board plane. If the LEDs have the same emission behavior, the same secondary lenses and reflectors can be used. This means that neither the LED components nor the end application are changed in terms of their characteristics.

Making the most of the benefits

The new concept makes it much easier to handle LED components from different manufacturers because there is no longer the need to make modifications to the board design. What's more, there is no need for duplicated storage, reducing costs still further. Dr. Gartner sums up the benefits as follows: "The efficiency and performance of our Oslon family is undisputed worldwide. The concept for a flexible solder pad design gives our customers the freedom to incorporate a second source for our high-power LED components without having to suffer restrictions due to mechanical parameters."

For more technical information on the Oslon product family go to the product catalog; information on the solder pad design is available on the web page.

http://www.osram-os.com/pr-solderpad

ABOUT OSRAM OPTO SEMICONDUCTORS

OSRAM AG, a wholly owned subsidiary of Siemens, is one of the two leading lighting manufacturers in the world. Its subsidiary, OSRAM Opto Semiconductors GmbH in Regensburg (Germany), offers its customers solutions based on semiconductor technology for lighting, sensor and visualization applications. Osram Opto Semiconductors has production sites in Regensburg (Germany) and Penang (Malaysia). Its headquarters for North America is in Sunnyvale (USA). Its headquarters for the Asia region is in Hong Kong. Osram Opto Semiconductors also has sales offices throughout the world. For more information go to www.osram-os.com.

Press Contact:

Kate Cleveland

Tel. 248-684-1476

Fax 248-596-0395

Email: kate.cleveland@osram-os.com

Technical Information:

OSRAM Opto Semiconductors

Tel. 866-993-5211

e-mail: info@osram-os.com