Parallel Board-to-Board Connectors Feature Removable Caps for Low Profile SMT Connections

Press Release Summary:

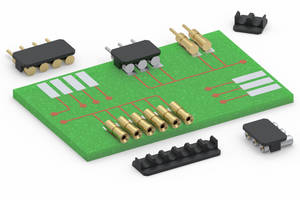

Mill-Max's new Horizontal SMT headers and sockets offer removable plastic caps that are capable of creating an interconnect system with minimal surface mount profile. The connectors feature an above-board profile of .096" wiht cap in place and .072" with the cap removed. They are single row with .100" pin spacing and are availble with 2-10 positions. These connectors are suitable for applications such as LED lighting systems where verticle board stacking is not an option.

Original Press Release:

Mill-Max Introduces Parallel Board-to-Board Connectors

Mill-Max Mfg. Corp., North America’s largest manufacturer of Precision Machined interconnects is proud to present new Horizontal SMT (HSMT) headers and sockets ideally suited for low profile parallel board-to-board or board-to-component mating. The removable plastic cap provides the convenience of a traditional connector and once removed delivers an interconnect system with a minimal surface mount profile.

These new sockets, 835-43-0XX-40-030001, and headers, 328-10-1XX-40-020001 are an excellent choice for applications where vertical board stacking is not an option, such as in LED lighting systems which often employ daisy-chained PCB’s to minimize overall package height. This new series of HSMT connectors have an above-board profile of .096” (2,44 mm) with the cap in place and just .072” (1,83 mm) with the cap removed. The cap serves multiple functions: it maintains accurate pin to pin spacing, enables group placement of low profile SMT pins and receptacles and provides a flat pick and place surface for efficient automated assembly. After soldering, it may be easily removed to achieve a minimal profile.

The connectors are single row with .100” (2,54 mm) pin spacing and are available in 2-10 positions. All are packaged on tape and reel (1,450 parts per 13” reel) per EIA-481 standards; tape widths vary with pin count. The cap material is high temperature Nylon with an HDT of 260° C to withstand most soldering processes.

Each pin and receptacle is precision turned from brass alloy. The receptacle has a highly reliable 4 finger, beryllium copper contact and accepts leads ranging from .015” - .025” (,38 - ,635 mm). The standard plating for the sockets is tin on the shell and gold on the internal contact providing optimal interconnect reliability. The header pins come standard with gold plating.

For more information, please visit http://www.mill-max.com/PR686.

About Mill-Max

Mill-Max is the leading US manufacturer of machined interconnect components with a vertically integrated manufacturing facility headquartered at 190 Pine Hollow Rd., Oyster Bay, NY 11771. Its full product line includes spring-loaded connectors, SIP, DIP, PGA and BGA sockets, board-to-board interconnects and pin headers, surface mount and custom products, PCB pins and receptacles, solder terminals, wrapost receptacles and terminals. The company’s complete manufacturing facility includes engineering, tooling, primary and secondary machining, stamping, plating, injection molding, and assembly.