Overlay System increases arc-on time and weld quality.

Share:

Press Release Summary:

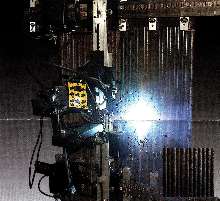

All Position Mechanized Overlay System consists of 2 parallel drives, tied together with cross boom for automatic indexing, and vertical drive, with torch oscillation. Weld current sensing height control is incorporated to maintain torch arc length on pitted, irregular surfaces. Suitable for rebuilding vessels and boiler tubes, portable system can be broken down for moving through small manholes and openings.

All Position Mechanized Overlay System consists of 2 parallel drives, tied together with cross boom for automatic indexing, and vertical drive, with torch oscillation. Weld current sensing height control is incorporated to maintain torch arc length on pitted, irregular surfaces. Suitable for rebuilding vessels and boiler tubes, portable system can be broken down for moving through small manholes and openings.Original Press Release:

All Position Mechanized Overlay System Increases Arc-On time and Weld Quality

BUG-O SYSTEMS Inc. announces the introduction of its new All Position Mechanized Overlay System for rebuilding vessels and boiler tubes. Consisting of two parallel drives tied together with a cross boom for automatic indexing and a vertical drive with torch oscillation, the All Position Overlay System can provide consistent uniform overlay patterns on a variety of surfaces. A weld current sensing height control is incorporated so as to maintain the torch arc length on pitted, irregular surfaces. The system can be customized for job specific applications on circumferences or flat walls and can be configured to handle a variety of operating windows. The whole system is portable and can be broken down into small pieces for moving thru small manholes or openings.

For more information on the All Position Mechanized Overlay System contact: BUG-O Systems, 3001 West Carson Street. Pittsburgh, PA USA 15204-1899 Phone: 1-800-245-3186 ext. 23, Fax: 1-412-331-0383 http://www. bugo.com