Operations Management Software includes QC functionality.

Share:

Press Release Summary:

Promoting operational efficiency, regulatory compliance, and product safety, Wonderware MES 2012 with Quality provides operations and performance management functionality along with quality management for sample data collection, statistical process control, and quality results monitoring. Product, equipment, and process-related quality data, captured in near real-time for automated and manual operations, helps plant operators respond to abnormal conditions, quality trends, and deviations.

Original Press Release:

Invensys Introduces New Quality Management Software

-- Wonderware MES 2012 with Quality increases efficiency, compliance and product safety --

HOUSTON, TEXAS – Invensys Operations Management, a global provider of technology systems, software solutions and consulting services to the manufacturing and infrastructure operations industries, has released an updated version of its Wonderware MES software. The newest version expands existing operations and performance management functionality by adding quality management for sample data collection, statistical process control and quality results monitoring, helping to improve operational efficiency, regulatory compliance and product safety.

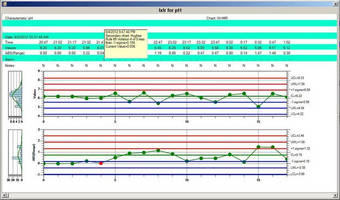

Wonderware MES Software 2012 with Quality reduces the cost of quality management while improving regulatory and product safety compliance by capturing complete product, equipment and process-related quality data for both automated and manual operations. The software monitors quality data in near real time so plant operators can respond faster to non-conformance conditions, quality trends and deviations, as well as to take corrective actions that minimize variations and bring quality closer to specifications. It complements existing enterprise quality management systems with sample plan execution automation, higher accuracy in shop-floor quality sample data, integrated statistical process control (SPC) and enhanced work order and operational execution context.

“Our Wonderware MES 2012 with Quality software integrates manufacturing operations and quality operations in production and addresses a key challenge in synchronizing production schedules and the required quality procedures,” said Rob McGreevy, vice president of platform and operations software at Invensys Operations Management. “Enhancements to the software reduce distracting and difficult-to-manage operator tasks, as well as secure compliance and product safety in ever-changing environments. Integrating systems, data and processes enables better operations management and increases value within manufacturing. We’ve enhanced our MES software because users demand improved operational efficiency and reduced complexity, which allows them to better manage all their operational activities and improve their overall business performance.”

The new features of Wonderware MES 2012 with Quality software build out the quality management capabilities of the original version. The software now enforces manual and automatic data collection and integrates structured sampling plans, as well as includes rigorous SPC. The updated software also allows sampling plans to be dynamically generated, according to current work-order status for products, equipment and operations. Execution of the sample plans can be done according to system quality specifications, and the samples themselves can be automated, from equipment, control systems or instrumentation. SPC trending and charting are available for near real-time quality monitoring, and include notifications of violations of control and specification limits.

“The new feature-rich operations, performance and now quality-management capabilities can be incrementally deployed,” McGreevy said. “Our Wonderware MES software is configurable, providing reusable and sustainable manufacturing operations management solutions with a low total cost of ownership and high return on investment when deployed as an enterprise standard across multiple lines and plants.”

About Invensys Operations Management

Invensys Operations Management, a division of Invensys, is a leading provider of automation and information technology, systems, software solutions, services and consulting to the global manufacturing and infrastructure industries. Headquartered in Houston, Texas, its solutions are used by more than 40,000 clients around the world in more than 200,000 plants and facilities.

Invensys Operations Management’s offerings are delivered under several prominent industry brands, including Avantis, Eurotherm, Foxboro, IMServ, InFusion, SimSci-Esscor, Skelta, Triconex and Wonderware. The company’s approximately 9,000 employees and its global partner ecosystem integrate these products and services to help clients collaborate across systems and enterprises in real time, extracting critical data to make faster, better decisions and synchronize their operations from the plant floor to the executive offices, aligning production goals with business objectives. To learn more about Invensys Operations Management, visit iom.invensys.com.

Experience the value of Enterprise Control—linking business strategy to production execution—at www.infusionjourney.com.

Invensys, the Invensys logo, Avantis, Eurotherm, Foxboro, IMServ, InFusion, SimSci-Esscor, Skelta, Triconex and Wonderware are trademarks of Invensys plc, its subsidiaries or affiliates. All other brands and product names may be trademarks of their respective owners.