New Yaw-Pitch Stages from OES are Capable of Rotating Large Angles

Press Release Summary:

- Available in YP110-10-01 (stepper motor driven), YP110-10-02 (brushless servo motor driven) and YP110-10-03 (DC servo motor driven)

- Features 180:1 ratio gear and are ideal for precise measurement of angles or the curvature of an object

- Offers 0.05 degrees positional accuracy and +/- 0.01 degrees repeatability

Original Press Release:

Motorized Yaw-Pitch Stages Available from OES!

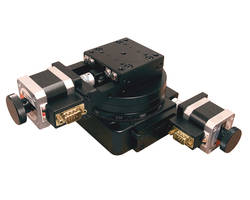

Van Nuys, CA – OES (Optimal Engineering Systems, Inc.) has introduced three high accuracy Yaw-Pitch stages. The YP110-10-01 (stepper motor driven), the YP110-10-02 (brushless servo motor driven) and the YP110-10-03 (DC servo motor driven). The Yaw-Pitch stages are ideal for the precise measurement of angles or the curvature of an object.

The pitch stage has cross roller guides and a range of travel of +/- 10 degrees. The maximum speed is 14 degrees per second with stepper motor driven version and 90 degrees per second with the servo motor driven versions. The 65 mm x 65 mm table has a precise pattern of threaded holes for fixtures or tooling and has an accuracy of 0.05 degrees and repeatability of +/- 0.01 degrees.

The rotation center height is 75 mm and the pitch axis is equipped with end of travel limit switches to signal the motion controller to stop the motion at each end. This axis also has the calibrated indicator to display the angle of rotation.

The yaw stage is capable of rotation of large angles and features a 180:1 ratio gear. The positional accuracy is 0.05 degrees and repeatability is +/- 0.01 degrees. This axis also has a calibrated indicator to display the angle of rotation and HOME signal for initialization.

The knobs of the stepper motors can be replaced with an optional optical encoder for precision position verification. The YP110-10-02 and YP110-10-03 feature servo motors and optical encoders for very precise closed loop operation and greater travel speeds.

Each of the stages can be ordered plug-and-play with a fully compatible multi-axis motion controller from OES.

About OES – Optimal Engineering Systems, Inc. (OES) is a manufacturer of motion control products including: Stepper motor controllers and drivers, solenoid electronics, and positioning stages and slides. Applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.

Some of the industries OES serves are: Aerospace, Astronomy, Chemical, Communications, Educational Institutes, University, Colleges, Government Agencies, National Labs, Manufacturing, Medical, Metrology, Military, Motion Control, Museum, News Agencies, Semiconductor and Test Equipment. Optimal Engineering Systems, Inc's. competitive advantage is its state-of-the-art in-house manufacturing facility in North America enabling OES to supply clients with custom designed orders or high volume just-in-time deliveries globally.

For additional information, contact our sales team at: OES, 6901 Woodley Ave.;

Van Nuys, CA 91406; Telephone: 888-777-1826 or +1 818-222-9200, or E-Mail: sales@oesincorp.com or visit the Web site at: http://www.oesincorp.com.

For additional information please contact:

US PR contact:

Don Wismann

760-497-0776

dwtechcom@gmail.com