New Wet Electrostatic Precipitator Eliminates Carryover of Entrained Matter During Washing

Press Release Summary:

- Offers efficient contaminant capture through increased operating voltage, requiring less collecting surface area

- Reduces maintenance and provides good operational performance during cleaning

Original Press Release:

Dürr Introduces “next generation� Wet ESP

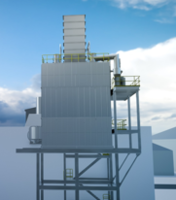

Bietigheim-Bissingen, Germany, February 16, 2021 – Dürr Megtec recently released its “next generation” wet electrostatic precipitator (WESP) – an air pollution control system that efficiently cleans industrial gases of fine particulate matter, acid mists and aerosols to meet global environmental regulations and protect downstream equipment. Key improvements of Dürr Megtec’s advanced WESP system include decreased maintenance, enhanced performance, standardization and faster installation times.

Dürr Megtec, part of the Clean Technology Systems division of the Dürr Group, designed the new WESP with both the environment and its customers’ operations and maintenance teams in mind. As a result, a strong focus was placed on the system’s high-intensity, offline automatic cleaning features, which reduce maintenance efforts, eliminate carryover of entrained matter during washing and provide better operational performance during cleaning. System components are also now easily accessible for maintenance inspections.

Increased efficiency

In order to enhance the performance of its WESP, Dürr aimed at achieving a more efficient contaminant capture. This was achieved through increased operating voltage that requires less collecting surface area. Additionally, the gas distribution system was completely reimagined to optimize flow through the system, and various tube shapes and electrodes were tested to improve overall performance.

Reduced fabrication and installation time

Standardized modules are used in the new design, thus reducing engineering time and streamlining fabrication. The systems are assembled from different standard modules and adapted to customer-specific requirements.

Time is always of the essence, so the “next generation” WESP allows for faster installation times. Modules with tube bundles are pre-assembled in the production facility for shipment to the customer. All electrodes are pre-loaded and pre-aligned, thus avoiding this lengthy and tedious task on the construction site. When compared to other commercially available WESP designs, the manufacturing and installation timeline of the advanced Dürr product is dramatically lower.

WESP air pollution control systems are used in all sectors of industry, including wood, waste incineration, food processing, biofuels, metals and mining, chemical, petrochemical, iron and steel, and pulp and paper. Dürr WESPs can remove up to 98 percent of particulate in a single stage, depending on the characteristics of the gas stream. Increased removal efficiency is possible with alternative configurations.

Application-oriented development

Dürr’s WESP is an established product in the air pollution control market.

“After talking to our customers, our product development departments generated innovative, patent pending ideas in the area of particulate removal efficiency, and tube and electrode cleaning – all with a keen eye towards reduced maintenance and increased reliability,” says Dr. Daniel Schmitt, President & CEO of Dürr’s Clean Technology Systems division.

Numerous scale models were used to establish proof of concept before ideas were implemented. Based on that work, extensive field-testing was done under real-life conditions with large, to-scale equipment. Results of the pilot program were used to prove final concepts and performance prior to commercial scale production.

“The next generation design addressed industry-specific feedback obtained from users and operators,” adds Dr. Schmitt. “We are excited to get this equipment to the market, so that both our customers and the environment can benefit.”

For more information about Dürr’s advanced WESP, watch the video and visit our website https://www.durr-megtec.com/en/products/exhaust-gas-and-air-pollution-control/separation-processes/wet-esp

The Dürr Group is one of the world's leading mechanical and plant engineering firms with extensive expertise in automation and digitalization/Industry 4.0. Its products, systems and services enable highly efficient manufacturing processes in different industries. The Dürr Group supplies sectors like the automotive industry, mechanical engineering, chemical, pharmaceutical and woodworking industries. It generated sales of € 3.92 billion in 2019. The company has around 16,200 employees and 112 business locations in 33 countries. The Group operates in the market with the brands Dürr, Schenck and HOMAG and with five divisions:

- Paint and Final Assembly Systems: paint shops as well as final assembly, testing and filling technology for the automotive industry

- Application Technology: robot technologies for the automated application of paint, sealants and adhesives

- Clean Technology Systems: air pollution control, noise abatement systems and coating systems for battery electrodes

- Measuring and Process Systems: balancing equipment and diagnostic technology

- Woodworking Machinery and Systems: machinery and equipment for the woodworking industry