New Waterjet Deburring and Cleaning Machine is Integrated with CAD / CAM Interface

Press Release Summary:

- Able to process parts with dimensions up to 200 x 200 x 200 mm cycle times in 15 seconds per palette

- Component cleaning and drying are carried out by injection flood washing, spraying, controlled rinsing and ultrasound

- Can be loaded automatically with a robot or portal system as well as manually

Original Press Release:

Innovative All-Round Talent for Deburring and Cleaning in One-Piece Flow

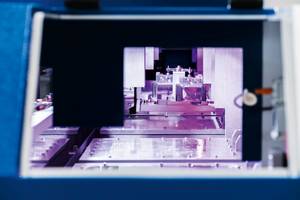

EcoCvelox – high-pressure waterjet deburring combined with low-pressure processes for cleaning

Process-reliably and reproducibly deburred and cleaned parts are crucial for the quality of subsequent processes such as bonding, sealing and assembly as well as for perfect product function. With the completely new system concept EcoCvelox, Ecoclean introduces a highly flexible, modular solution for cost-efficient high-pressure waterjet deburring and cleaning in a single procedure. The process-dependent configurable and expandable machine with integrated linear transport system enables processing of parts with dimensions up to 200 x 200 x 200 mm cycle times of only 15 seconds per palette in the so-called one-piece flow. An integrated CAD / CAM interface allows for quick and easy programming of the high-pressure deburring process – either with a single spindle or a high-pressure turret with up to five tools. In combination with an innovative system for parts handling, it ensures that process operations for new workpieces can be implemented in the shortest possible time. Component cleaning and drying can be carried out by means of injection flood washing, spraying, controlled rinsing and ultrasound, as well as high-speed blowing and vacuum drying. The system can be loaded automatically with a robot or portal system as well as manually.

The SBS Ecoclean Group develops, produces and markets forward-looking machinery, systems and services for industrial part cleaning and surface treatment applications. Its globally leading solutions help companies around the world in conducting efficient and sustainable manufacturing to high quality standards. The client base comes from the automotive industry and its suppliers in addition to a broad range of market sectors ranging from medical equipment, micro technology and precision devices through mechanical and optical engineering to power systems and aircraft industry. Ecoclean's success is based on innovation, cutting-edge technology, sustainability, closeness to the customer, diversity and respect. The Group employs a workforce of approx. 900 at its 12 sites in nine countries worldwide.