New Unsealed Connectors Include Reduced Mating Force Below 75 N

Press Release Summary:

- AMP MCP 18P monoblock connector uses AMP MCP 2.8 contact system

- Fits into bulkhead cut-outs and the required secondary locking feature helps to keep contacts aligned

- Ideal for bulkhead, in-cabin and fuse-and-relay-box applications

Original Press Release:

TE Connectivity Improves Transportation Industry’s Safety and Ease of Assembly with New Unsealed Connectors

Next-generation AMP MCP connectors are flame retardant and easily fit into existing bulkhead cut-outs

Winston-Salem, N.C. – Oct. 1, 2019 – Offering improved safety and ease of assembly over other industry models, TE Connectivity (TE), a world leader in connectivity and sensors, launched a new addition to its unsealed connector portfolio for the transportation industry. The AMP MCP 18P monoblock connector offers trust and reliability in harsh environments for industrial and commercial transportation with its flame retardant composition and new lever design.

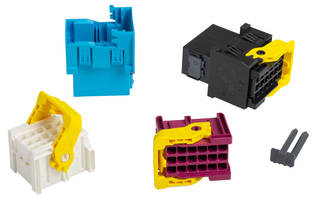

Ideal for bulkhead, in-cabin and fuse-and-relay-box applications, these unsealed monoblock connectors use the widely known AMP MCP 2.8 contact system, have a reduced mating force below 75 N, and can easily be used for new or existing designs. They conveniently fit into existing bulkhead cut-outs and the required secondary locking feature helps to keep contacts aligned.

“Electrical networks become more and more complex while regulations are constantly increasing. That’s why it’s imperative that truck, bus, auto, construction and agriculture-equipment operators have connector solutions they can trust, thereby minimizing one potential aspect of complexity,” said Girish Medh, product manager, Industrial and Commercial Transportation, TE Connectivity. “Our design and engineering teams heard what transportation operators said about the need for a next- generation connector. We met that need with these state-of-the-art connectors and will continue to innovate by keeping our customers involved with our product design and development.”

The flame-retardant UL 94 V-0 material from which the connectors are made increases their safety factor, as does the required secondary locking feature. In addition, the four available colors ensure proper mating and help ease assembly.

Visit www.te.com/ict for more information.

About TE Connectivity

TE Connectivity Ltd. is a $14 billion global technology and manufacturing leader creating a safer, sustainable, productive, and connected future. For more than 75 years, our connectivity and sensor solutions, proven in the harshest environments, have enabled advancements in transportation, industrial applications, medical technology, energy, data communications, and the home. With 80,000 employees, including more than 8,000 engineers, working alongside customers in approximately 140 countries, TE ensures that EVERY CONNECTION COUNTS. Learn more at www.te.com and on LinkedIn, Facebook, WeChat and Twitter.

Media Relations:

Mark Pepe

TE Connectivity

Phone: +1 484 843 4460