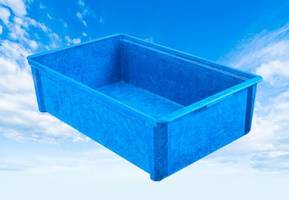

New ULTRA LITE Totes and Containers are Light and Durable

Press Release Summary:

- Help improve shop ergonomics and lower shipping weight

- Products are strong than standard thermoplastic as well as withstands temperatures from –60 to 250 F

- Impervious to cutting oils, detergents, mild acids and alkaline solutions

Original Press Release:

MFG Tray’s New ULTRA LITE Totes and Containers Combine Lighter Weight with Legendary Strength

New product line is 40% lighter while retaining trusted strength and durability of MFG’s fiber glass reinforced composite.

Linesville, PA -- Can an industrial container be made lighter and still retain its strength? That’s the challenge engineers at Molded Fiber Glass Tray have answered with the development of MFG Tray’s new ULTRA LITE totes and containers.

The new line of ULTRA LITE products are 40 percent lighter than standard fiberglass products while retaining the trusted strength and durability of MFG’s fiber glass reinforced composite, said Burt Hovis, MFG Tray material handling product line manager.

“ULTRA LITE is a direct result of customer requests to help improve shop ergonomics and lower shipping weight,” noted Hovis. “ULTRA LITE totes and containers answer industry-wide needs to reduce weight per container and to counter escalating shipping costs and weight.”

Hovis added that MFG Tray’s engineering team knew the finished product also had to be tough and long-lasting, similar to the company’s well-known MFG Tray brand.

“Even at 40% lighter, our new ULTRA LITE fiber glass products will be stronger than standard thermoplastic, can withstand temperatures from –60 to 250 F and are impervious to cutting oils, detergents, mild acids and alkaline solutions,” said Hovis.

MFG Tray will introduce its new line of ULTRA LITE totes and containers at the MODEX 2020 trade show, set for March 9-12 in Atlanta, Ga.

Molded Fiber Glass Tray, MFG Tray, is a leading manufacturer of high-strength, glass-reinforced composite containers, trays, boxes, flats and totes for material handling in the metalworking, plastics and electronics assembly industries, as well as in food service, confectionery and pharmaceutical processing. Based in Linesville, Pa., the company continually develops customized solutions for specific material-handling challenges and applications.