New Simulation Solution Improves Quality for DED Metal Additive Manufacturing Processes

Press Release Summary:

- Enables the user to set up robust DED simulation models by importing existing tool paths direct from G-Code instead of defining weld paths manually

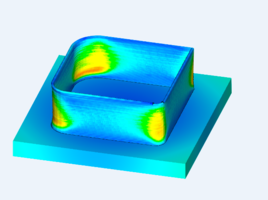

- Evaluates the stresses, strains, distortions, thermal history and hot spots during the manufacturing to clearly identify distortions that are out of tolerance and recommend compensations

- User can adapt the G-code to optimize the DED printing process and improve quality

Original Press Release:

Simufact Improves Quality with New Dedicated Simulation Solution for Direct Energy Deposition 3D Printing

New Direct Energy Deposition (DED) capability models manufacturing processes directly from G-Code

Formnext 2019, Frankfurt am Main, November 20, 2019 – Simufact, a global operating software company providing process simulation solutions and services to manufacturing industries, today announced a dedicated simulation solution to help manufacturers improve quality for Direct Energy Deposition (DED) metal additive manufacturing processes.

Offered as a module inside its Simufact Welding 2020 software, it enables the user to quickly set up robust DED simulation models by simply importing existing tool paths direct from G-Code instead of defining weld paths manually. The software evaluates the stresses, strains, distortions, thermal history and hot spots during the manufacturing to clearly identify distortions that are out of tolerance, and recommend compensations. Based on this, the user can adapt the G-code to optimize the DED printing process and improve quality.

DED incorporates several metal 3D printing technologies that create parts by melting and fusing material as it is deposited, and is also known as 3D Laser Cladding, Wire Arc Additive Manufacturing (WAAM), Direct Metal Deposition (DMD), or Laser Metal Deposition (LMD). It’s typical fields of application are repairing and rebuilding damaged parts, but also manufacturing of new large metal parts that may not be possible with Powder Bed Fusion.

“We are seeing significant demand for our new simulation solution because it helps to optimize such cost-efficient deposition production processes. DED offers a lot of innovation potential for hybrid manufacturing that combines conventional manufacturing technologies with additive manufacturing.” explained Dr. Hendrik Schafstall, CEO and Managing Director at Simufact Engineering.

About Hexagon | Simufact

Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications.

Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Simufact, part of Hexagon’s Manufacturing Intelligence division, is a global operating software company providing process simulation solutions and services to manufacturing industries. Learn more at simufact.com. Hexagon’s Manufacturing Intelligence division provides solutions that utilise data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagonmi.com.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 20,000 employees in 50 countries and net sales of approximately 3.8bn EUR. Learn more at hexagon.com and follow us @HexagonAB.

Press Contacts:

Volker Mensing

Director Marketing & Communications

+49 (0)40 790128-160

volker.mensing@simufact.de

Penelope Friebel

Public Relations & Social Media

+49 (0)40 790128-164

penelope.friebel@simufact.de