New Self-cleaning Filtration System Reduces The Number of Filter Changes

Press Release Summary:

- Reduces associated downtime thereby lowering total costs and reducing environmental waste

- Automated to clean itself by monitoring the rise in differential pressure across the inlets and outlets due to contaminant loading

- Ideal for plating applications used in lighting and plumbing fixtures, appliances, automotive and mechanical hand tools

Original Press Release:

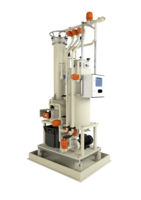

CECO Mefiag Introduces New Eco-friendly, Self-cleaning Filtration System That Significantly Improves Customer Productivity

Dallas, April 13, 2021 /PRNewswire/ -- CECO Environmental Corp. ("CECO," "CECO Environmental") (NASDAQ: CECE), a global leader in providing environmental and equipment solutions to a variety of end markets, is pleased to announce the release of a new patent-pending Self-Cleaning Filtration System that significantly reduces the number of filter changes and associated downtime thereby lowering total costs and reducing environmental waste. The system is designed for plating applications used in lighting and plumbing fixtures, appliances, automotive, aerospace, electronics, coinage, fasteners, and mechanical hand tools.

"We are excited to offer this purpose-built solution that meets our customer needs for lowering annual maintenance costs, increasing uptime, and reducing environmental waste with this more sustainable and environmentally friendly technology," says Chris Tsourides, President of CECO's Industrial Air and Fluid Solutions segment. "The self-cleaning filter system is automated to clean itself by monitoring the rise in differential pressure across the inlets and outlets due to contaminant loading. As contaminants accumulate on the filter media product flow through decreases," continues Tsourides. "CECO Mefiag has almost 70 years of experience developing turnkey fluid delivery systems (pumps, filtration, valves, pressure vessels, piping, control panels, skid mounted) and this patent-pending design continues the rich history of innovation from CECO."

The Self-Cleaning Filter System replaces conventional filter systems. Traditionally, end users of plating processes opt for disposable filter media due to the low initial cost, but don't consider the total life-cycle cost of the filter. Depending on the process, scale and frequency, maintenance costs could range from $10,000 to $100,000 annually not including lost downtime. With CECO Mefiag's new Self-Cleaning Filtration System, customers can expect to benefit from an estimated 75% in cost savings or greater compared to replacement filters.

"The new CECO Mefiag Self-Cleaning Filtration System enables higher productivity for our customers," said Lars Theunissen, General Manager of CECO Mefiag. "With our Self-Cleaning solution, our customers will reduce downtime as well as the regulatory paperwork and processes associated with disposing of alternative filter systems. Additionally, we improve employee safety by reducing exposure to VOCs (volatile organic compounds) and potential chemical spills that may occur during routine filter change-outs."

More information can be found by visiting https://www.cecoenviro.com/ceco-mefiag-new-self-cleaning-filters

About CECO Environmental

CECO Environmental is a global leader in air quality and fluid handling serving the energy, industrial and other niche markets. Providing innovative technology and application expertise, CECO helps companies grow their business with safe, clean, and more efficient solutions that help protect our shared environment. In regions around the world, CECO works to improve air quality, optimize the energy value chain, and provide custom-engineered solutions for applications including oil and gas, power generation, water and wastewater, battery production, polysilicon fabrication, chemical and petrochemical processing along with a range of others. Learn more by visiting www.cecoenviro.com.

Source CECO Environmental Corp.

Contact:

Hila Shpigelman

hshpigelman@onececo.com