New Robot Control Mate Software Provides Configuration and Virtual Commissioning Before Installation

Press Release Summary:

- Allows to commission and control SCARA robots direct from laptop and computers

- Can be used to control the physical movements of robot in real-time and makes robot programming possible when FlexPendant is not in place

- Offers offline programming tool that enables users to create, simulate and test complete robot installation in virtual 3D environment

Original Press Release:

ABB Expands RobotStudio® with Ability to Control SCARA Robots from PC

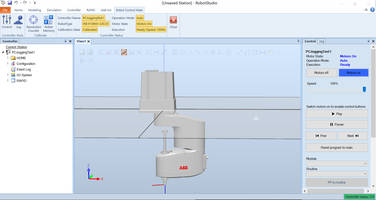

RobotStudio’s new Robot Control Mate add-on allows users to easily commission and control SCARA robots direct from their laptop and computers

ABB has simplified the use of its popular SCARA robots by giving users the ability to commission and control the robots from their PC through RobotStudio®, ABB's simulation and offline programming software.

Robot Control Mate is an add-on to RobotStudio, enabling users to jog, teach and calibrate robots from their computer, making it easier than ever to control a SCARA robot’s movements. For the first time, ABB’s offline programming software can be used to control the physical movements of a robot in real-time. Robot Control Mate also makes robot programming possible when a FlexPendant is not in place.

Robot Control Mate will first be available on the IRB 910INV ceiling-mounted robot and will be expanded to other robots in ABB’s portfolio later this year.

RobotStudio is the industry’s leading PC-based solution for programming, configuration and virtual commissioning before installation. ABB’s offers a complete digital twin of physical assets or systems on a production line. The offline programming tool enables users to create, simulate and test a complete robot installation in a virtual 3D environment without disturbing their actual production line. This means that new production lines can be installed faster and ramped up to full speed without surprises during commissioning – a critical competency for manufacturers given the shift to mass customization and shorter product life cycles.

“Simplifying the installation, programing and operation of robots offers our customers so many benefits, including offsetting talent shortages and helping SMEs become new robot users,” said Darren Hung, ABB’s Global Product Manager for small robots. “Adding our new Robot Control Mate functionality to RobotStudio will make it even more straightforward to set-up robotic automation solutions, while users can enjoy the increased flexibility of operating their robots from their laptops.”

For more information please visit: https://new.abb.com/products/robotics/robotstudio/robot-control-mate

ABB (ABBN: SIX Swiss Ex) is a technology leader that is driving the digital transformation of industries. With a history of innovation spanning more than 130 years, ABB has four, customer-focused, globally leading businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation, supported by the ABB Ability™ digital platform. ABB’s Power Grids business will be divested to Hitachi in 2020. ABB operates in more than 100 countries with about 144,000 employees. www.abb.com

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, we have shipped over 400,000 robot solutions. We help our customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. We support their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 10,000 people at over 100 locations in more than 53 countries. www.abb.com/robotics

For more information please contact:

ABB Robotics US Media Relations

Alex Miller

Phone: 262-236-3710

Email: alex.x.miller@us.abb.com