New Receptacles Designed to Work with Shorter Mating Leads

Press Release Summary:

- Designed to be soldered in a .071” minimum mounting hole

- Fitted with beryllium copper contact clip

- Accepts lead diameters from .037” - .043” with minimum mating lead length of .058” for top entry insertion

Original Press Release:

Mill-Max Expands Early Engagement Receptacle Lineup

Receptacles designed to accept mating leads of .040” (1,02 mm) diameter with a minimum length of .058” (1,47 mm)

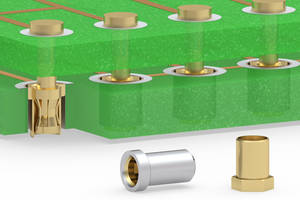

Oyster Bay, NY, 17 September 2019 – Mill-Max Manufacturing Corp., Inc. announces the development of a new minimal insertion length contact, expanding our range of receptacles designed to work with shorter mating leads. The receptacles being introduced here are fitted with a new, beryllium copper contact clip which is characterized by an early engagement contact point, dual entry capability, low contact resistance and high current carrying capacity.

The 0448-0-15-15-48-27-10-0 and 0640-0-15-15-48-27-10-0 receptacles accept lead diameters from .037” - .043” (,94 – 1,09 mm) with a minimum mating lead length of .058” (1,47 mm) for top entry insertion. This is a 30% reduction in required lead length from our current receptacle offerings. The reduction is due to the hourglass design and extended contact surface area, eliminating the need for excess protrusion through its fingers for reliable electrical contact. The ability to use shorter mating pins provides several advantages such as compressed packaging, shorter electrical signal paths and lower potential RF signal interference.

The 0448 is a closed bottom, solder mount receptacle with a .025” (,635 mm) low profile height above the board. It is designed to be soldered in a .071” (1,8 mm) minimum mounting hole. The 0640 is a zero profile, solderless press-fit receptacle with an overall length of .105” (2,67 mm). This part features a hexagon shaped head designed to be press-fit into a .085” (2,16 mm) ǿ plated through hole. When pressed in, the 0640 sits flush with the P.C.B. surface. The 0640 is also open bottom allowing for mating pin entry from either end. The minimum mating pin length for bottom entry is .060” (1,52 mm) from the bottom of the receptacle. This dual entry feature allows for flexibility in component placement and assembly of boards and modules.

The receptacle shells are precision turned from brass alloy, featuring tight tolerances and a highquality finish. The contact clip is press-fit into each receptacle shell forming a gas-tight connection. It is a four-finger contact, precision stamped from Beryllium Copper strip & heat treated to provide excellent spring & electrical properties. Both receptacles have a current rating of 20 Amps at a 10˚C temperature rise above ambient, in free air, and less than 20 milli-ohms contact resistance. The standard plating for these receptacles is 10 u” gold on the shell and 30 u” gold on the contact to ensure the highest conductivity, corrosion resistance and durability. Tin and tin/lead plating options are also available upon request for the 0448.

About Mill-Max

Mill-Max is the leading US manufacturer of machined interconnect components with a vertically integrated manufacturing facility headquartered at 190 Pine Hollow Rd., Oyster Bay, NY 11771. Its full product line includes spring-loaded connectors, SIP, DIP, PGA and BGA sockets, board-to-board interconnects and pin headers, surface mount and custom products, PCB pins and receptacles, solder terminals, wrapost receptacles and terminals. The company’s complete manufacturing facility includes engineering, tooling, primary and secondary machining, stamping, plating, injection molding, and assembly.