New RDC-3030-SS DeClumper Lump Breaker is Equipped with Dual Independent 10 HP Motors

Press Release Summary:

- Designed at 279 mm high and fit in restricted spaces between bulk storage, handling, processing and packaging equipment

- Constructed of #304 stainless steel, #316 stainless steel, carbon steel and abrasion-resistant steel (AR-235)

- Equipped with interlocked side-removal bedscreens

Original Press Release:

Sanitary Lump Breaker has Dual Drives, Side Removal Screens

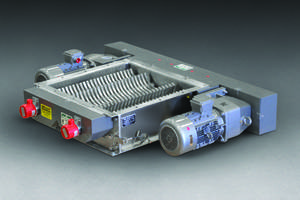

UTICA, NY - A new DeClumper™ lump breaker model RDC-3030-SS from Munson Machinery reduces agglomerates and compacted materials to original particle sizes.

At 11 in. (279 mm) high, it fits in restricted spaces between bulk storage, handling, processing and packaging equipment. With optional feed hoppers and support bases, it can also operate independently.

Material entering the 30 in. (762 mm) square inlet is reduced in size by four rotors with three-point, single-piece breaking heads rotating with minimum clearance inside twin, curved, perforated bedscreens. On-size material exits through apertures in the bedscreens ranging from 1/32 (25 mm) diameter to 2-1/2 in. (64 mm) square.

Unlike conventional units that must be unbolted from upstream and downstream equipment to access bedscreens, the unit is equipped with interlocked side-removal bedscreens that can be removed without tools for cleaning, changing or inspection.

Dual, independent 10 HP (7.5 kW) motors with gear reducer and chain and sprocket drives provide added capacity and redundancy, rotating the synchronized shafts at approximately 120 RPM to avoid heating the product.

The unit is recommended for deagglomeration of free- or non-free-flowing bulk chemicals, fertilizers, flakes, cement powders, carbon black pellets or hygroscopic products, and size reduction of large chunks of friable products and compacted powders.

According to the company, it is constructed to withstand heavy usage and is simple to maintain; bearings can be lubricated through external fittings and are isolated from the product processing area with air purge block seals, and can be fitted with optional air purge packing seals with split housings.

It is constructed of #304 stainless steel finished to sanitary standards and is available in #316 stainless steel, carbon steel, and abrasion-resistant steel (AR-235).

Other models are available with one to four rotors, single or dual motors, and inlets/outlets from 12 to 48 in. (305 to 1220 mm) in square or rectangular configurations.

Other size reduction machinery offered by the company includes Screen Classifying Cutters, Pin Mills (Centrifugal Impact Mills), Attrition Mills, Knife Cutters, Hammer Mills and Shredders. Blending equipment includes Rotary Batch Mixers, Ribbon/Paddle/Plow Blenders, Fluidized Bed Mixers, Vee Cone Blenders, Rotary Continuous Mixers and Variable Intensity Continuous Blenders.

EDITORIAL CONTACT:

Susan Schaaf, Rapp Advertising, Inc.

150 Morris Ave, Suite 200, Springfield, NJ 07081-3004

1-973-467-5570 x118 • sschaaf@rappadvertising.com