New ProFlex C100 Prevents Bridging and Plugging of Sticky Material

Press Release Summary:

- Feeding system is small and fits on small extrudes

- Equipped with an integrated gearbox for turndown ratios of up to 1:120

- Used for the continuous feeding of bulk materials such as powder, granulates, pellets or fibers

Original Press Release:

Schenck Process Introduces ProFlex® C100

Round up of ProFlex® C family to smaller feed rates for masterbatch applications

Storage, filling and feeding – three processes for which Schenck Process can provide extensive process knowledge. From a product portfolio perspective, Schenck Process is now completing their offering to best meet market requirements: Meet the newest addition to the ProFlex® C family, the ProFlex® C100.

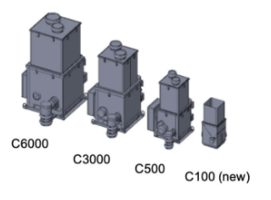

With ProFlex® C 500, 3000 and 6000, Schenck Process already offers three feeder sizes with a total of five extension hoppers. Now Schenck Process adds to their offering:

- Fit for small extruders: The new ProFlex® C100 is the smallest of the ProFlex® C family and as such also fits on small extrudes. It comes in low weight. Up to five feeders can be grouped around an inlet of a lab or small size extruder.

- Makes the customer flexible: A quick change hopper option in the ProFlex® line for fast and clean change over without disassembling of the feed screw. By keeping several hoppers including screw in stock, a wide range of additives and color pigments can be provided for in a highly flexible manner.

- Ready for sticky powders: The asymmetric design prevents bridging and plugging of sticky material.

- As quick as the customer: The new ProFlex® C100 is equipped with an integrated gearbox for turndown ratios of up to 1:120.

- Accuracy ensured: Flexible wall liner massaged at eight points, which allows a constant and accurate filling of the screw feed element.

- Prepared for the US market: It is NEMA drive ready for compounding and masterbatch, which is crucial for the US market.

The ProFlex® C feeding system is used for the continuous feeding of bulk materials such as powder, granulates, pellets or fibers. Optimized design, flexible hopper walls and flexible installation options make the ProFlex® C a tailored solution for the compound and masterbatch industries.

All of the Schenck Process ProFlex® C loss-in-weight feeder family for the compound and masterbatch industry is characterized by:

- Asymmetric design

- Easy change of discharge / drive side

- 8 point massage system

- Easy dismantling and cleaning

- Steep hopper walls

- LIW-critical cabeling encapusalted

All of these features are of course carried on in the new ProFlex C100.

Our abilities to design, size, sell, fabricate, and integrate other OEM processes as well as installing and providing ongoing support delivers full control. As the primary equipment manufacturer, we manage production schedules for faster lead times on highly-engineered, custom-built systems. The end result is a predictable, efficient, and effective material handling process solutions.

Contact us to make a scheduled appointment with our experts or meet us at K-Show in Düsseldorf, where the new ProFlex® C100 will be displayed at Booth 76 in Hall 11 from October 16-23, 2019.

Press Contact

Schenck Process Holding GmbH

Communications

Pallaswiesenstr. 100

64293 Darmstadt, Germany