New Probing Cycles Compatible with CNC Machines

Press Release Summary:

- Provides hassle-free post processing and full control over each probing routine

- Uses a sensitive touch probe to assess the dimensions of the workpiece

- Features offline inspection programming which offers users the benefits of virtual stimulation for program verification and collision detection

Original Press Release:

ESPRIT Announces Powerful Suite of Probing Cycles to Improve Setup and Accuracy

DP Technology, the parent company of the ESPRIT CAM system, introduces a new probing option that’s compatible with any combination of CNC machine, control, and touch probe manufacturer.

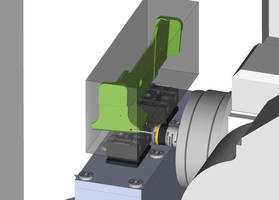

Camarillo, California (June 2020) – DP Technology, maker of the popular ESPRIT CAM software, now offers a suite of probing cycles. Probing, which uses a sensitive touch probe to assess the dimensions of the workpiece, is an important part of any machining process. Although probing support is not new for ESPRIT, the new features of the option make it a valuable addition for manufacturing professionals. These features include:

- Offline inspection programming, which offers users the benefits of virtual stimulation for program verification and collision detection

- Hassle-free post processing and full control over each probing routine

- Compatibility with more CNC machines and probe manufacturers

These new capabilities join the probing cycle’s existing features, such as:

- Misload detection, which confirms correct part loading and reduces the risk of damage

- On-machine inspection, which generates consistent measurements and eliminates manual measuring errors

- Dynamic tool offsets, which automatically adapt the program considering tool wear

Using the combination of ESPRIT probing and CNC machines outfitted with touch probes, shops will enjoy increased throughput on existing equipment while reducing operator intervention. This benefit comes along with increases in part consistency and quality.

To help users fully understand the complete capabilities of the new add-in, ESPRIT has produced a free webinar, which can be accessed any time here.

For additional information about DP Technology and ESPRIT, call +1 805 388 6000, email esprit@dptechnology.com, or visit www.espritcam.com.

About ESPRIT

ESPRIT® is a powerful CAM system for CNC programming, optimization and simulation — supporting the entire manufacturing process. With factory-certified post processors delivering machine-optimized G-code and ESPRIT’s ability to solve unique challenges with automation solutions, ESPRIT is the smart manufacturing solution for any machining application. With world-class technical support, ESPRIT empowers you to get started quickly and keep running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

About DP Technology Corp.

DP Technology Corp. is a leading developer and supplier of computer-aided manufacturing (CAM) software. ESPRIT®, DP Technology's flagship product, is a powerful, high-performance, full-spectrum programming system for milling, turning, wire EDM, multi-tasking machine tools and metal additive manufacturing. ESPRIT and its support personnel embody DP Technology's passion for excellence and vision of technology's potential.

DP Technology reinforces its commitment to technical excellence by dedicating nearly 20 percent of its annual revenue to ongoing research and product development. This long-term focus has produced powerful technological innovations that have placed ESPRIT in an industry-leading position since its market launch in 1985.