New Pitch-and-Roll Stages are Available with Servo Motors and Stepper Motors

Press Release Summary:

- Offers an expanded series to meet the specific requirements such as: angle range - 20° (± 10°), 30° (± 15°), and 90° (± 45°), height of rotation, size and load capacity

- Accuracies for repeatability are ± 4 minutes, positional accuracy ± 8 minutes, and backlash ± 3 minutes

- Measure angles of objects such as crystals, examining cutting edges of medical instruments, measurements of radiation patterns of LEDs and hyperspectral bidirectional reflectance

Original Press Release:

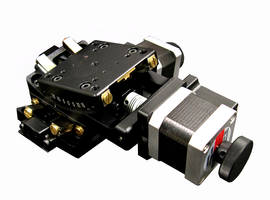

Pitch-and-Roll Stages from OES!

Van Nuys, CA – Measure Pitch-and-Roll, do micro machining, align mirrors for scanning electron microscopes, rotate objects to precise positions, measure angles of objects such as crystals or move an object to a precise angular position along an arc, examining cutting edges of medical instruments, estimating measurements of radiation patterns of LEDs, hyperspectral bidirectional reflectance, or provide orthogonal rotation (Def Orthogonal - Two lines or curves are Orthogonal if they are perpendicular at the point of intersection - Wolfram / MathWorld).

OES offers an expanded series of Pitch-and-Roll Stages to meet the requirements of the specific requirements of applications such as: Angle range - 20° (± 10°), 30° (± 15°), and 90° (± 45°), height of rotation, size (foot print), and load capacity. Typical accuracies for each stage are: Repeatability: ± 4 minutes (240 arc seconds), positional accuracy ± 8 minutes (480 arc seconds), and backlash ± 3 minutes (180 arc seconds).

The precision, Pitch-and-Roll Stages are available with either stepper motors with knobs for manual adjustment, or quadrature optical encoders on stepper motors for position verification. They are also available servo motors for closed loop operation and higher operating speed. The Pitch-and-Roll Stages can be supplied plug-and-play with a motion controller. Any of the Stacked Pitch-and Roll Stages are easily integrated into an inspection, testing, or manufacturing environment.

About OES – Optimal Engineering Systems, Inc. (OES) is a manufacturer of motion control products including: Stepper motor controllers and drivers, solenoid electronics, and positioning stages and slides. Applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.

Some of the industries OES serves are: Aerospace, Astronomy, Chemical, Communications, Educational Institutes, University, Colleges, Government Agencies, National Labs, Manufacturing, Medical, Metrology, Military, Motion Control, Museum, News Agencies, Semiconductor and Test Equipment. Optimal Engineering Systems, Inc's. competitive advantage is its state-of-the-art in-house manufacturing facility in North America enabling OES to supply clients with custom designed orders or high volume just-in-time deliveries globally.

For additional information, contact our sales team at: OES, 6901 Woodley Ave.;

Van Nuys, CA 91406; Telephone: 888-777-1826 or +1 818-222-9200, or E-Mail: sales@oesincorp.com or visit the Web site at: http://www.oesincorp.com.