New PCB Conformal Coating Inspection System Based on Mek AOI Technology

Press Release Summary:

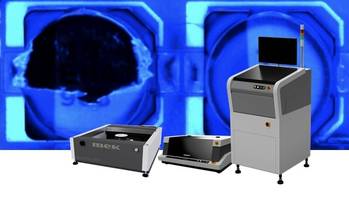

- iSpector JUz available as desktop, inline and on the modular SpectorBOX system

- Automates the conformal coating inspection process to ensure coating quality and consistency

- Inspects PCB and components as well as identifies coating issues including missing coating, bubbles and insufficient thickness

Original Press Release:

Fast & Simple PCB Conformal Coating Inspection

Mek (Marantz Electronics), leading supplier of 3D Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) technologies, has launched the iSpector JUz for conformal coating inspection.

Based on proven Mek AOI technology, the iSpector JUz automates the conformal coating inspection process to ensure coating quality and consistency.

Conformal coating inspection, (CCI) is an essential stage of the conformal coating process and yet one that very few companies undertake, aside from a brief manual visual inspection. But manual inspection is an extremely difficult job due to factors such as eye strain and concentration drift, while slow throughput makes it economically challenging.

Mek automated iSpector JUz CCI systems for automatic inspection of conformal coatings and defect detection see more than an operator ever could and make conformal coat inspection fast, simple and cost efficient.

Most Conformal Coating includes a UV florescent dye, typically in the 365 to 405nm range. UV light causes the coating to fluoresce which highlights discrepancies, contamination or process issues. Used after manual spray, automatic spray and dip coating applications, the system inspects the PCB and components and identifies coating issues including missing coating, bubbles, insufficient thickness, voids, coating in areas where not wanted and other common contaminations.

Unique algorithms and dedicated strategies allow easy and fast programming with high detection coverage. A comprehensive and easy to use online training suite is available via the Mek iMentor online training system.

The iSpector JUz is available as Desktop, Inline and also on the modular SpectorBOX system. http://marantz-electronics.com/ispector-juz/

About Mek (Marantz Electronics Ltd)

A former division of Marantz well known for its high quality Audio/Video products, Mek Japan (Marantz Electronics Kabushiki Kaisha), developed its first AOI system in 1994. Developed to inspect PCB assemblies for correct component placement and soldering, the company’s original AOI system was designed for use in Marantz factories. Proving to be a highly successful, cost-effective alternative to traditional human inspection, Mek developed its first generation commercial system in 1996. With a steadily growing installed base, MEK Japan and its European/American headquarters, Mek, have sold over 8000 units worldwide to date. Well established as a leading force in AOI technologies and 5D post-print SPI systems, the company now also manufactures Conformal Coating Inspection systems drawing on the proven technology.

MEK Contact:

Henk Biemans

MEK Europe

Polluxstraat 2B,

5047RB Tilburg

The Netherlands

Tel: +31 40 7114111

henk.biemans@mek-europe.com

www.marantz-electronics.com

Agency Contact:

Helena Osborn

Protean Inbound

Thames Valley Park, 400 Thames Valley Park Drive,

Earley, Reading, RG6 1PT, UK

Tel: 44 (0) 118 370 6015

helena@proteaninbound.com

www.proteaninbound.com