New PAC Project Software Suite R10 is Enhanced with Eight Control Commands

Press Release Summary:

PAC Project Software Suite R10 incorporates real-time control, HMI and data handling functionalities. The software enable user to designate individual I/O and variable tags for use in IIoT data communications. SNAP PAC are programmed using software suite. PAC software comes with OPC server, database connectivity, PC-based control configuration, more than 450 commands in English, graphical PID tuning and debugging features. The suite is designed for supporting MQTT/Sparkplug data communication.

Original Press Release:

Opto 22 Releases PAC Project Software Suite R10

Programming software combines real-time control, HMI and data handling functionality in a single integrated development environment to speed troubleshooting and improve communications.

Temecula, CA - May 15, 2018 – Opto 22 announces the release of PAC Project Software Suite R10. This release supports their new groov EPIC® system, adds eight new control commands, and provides the ability to designate individual I/O and variable tags as Public Access for read-only or read-write use in IIoT data communications via MQTT/Sparkplug. As in previous versions, HMI programming is included, and it uses the same tag name database as the real-time control engine, creating automatic integration between the two functions.

In the past, many process automation projects were solely focused on real-time control, but nowadays operator interface and data handling are often just as critical, sometimes more so. Therefore, it’s more important than ever for programming software to include not only a powerful real-time control engine, but also closely integrated human machine interface (HMI) and data handling functions, all in one integrated development environment.

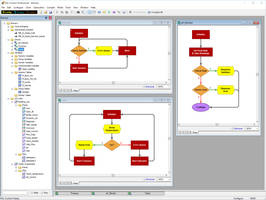

Opto 22’s industrial controllers—SNAP PAC programmable automation controllers and now groov EPIC edge programmable industrial controllers—are typically programmed using the PAC Project Software Suite. PAC Project Basic, free for download, includes flowchart-based control programming with optional scripting, a configuration utility and HMI development. PAC Project Professional adds an OPC server, database connectivity, PC-based control configuration and support for legacy Opto 22 I/O units. The Pro version sells for just under $1000.

The suite’s control programming software, PAC Control, is full-featured and easy to use, with more than 450 commands in plain English, plus graphical PID tuning and debugging.

HMI programing is provided with PAC Display. PAC Display Basic is a user-friendly HMI package for building operator interface applications to communicate with groov EPIC processors, SNAP PAC controllers and Ethernet-based I/O units. PAC Display offers rich features including alarming, trending, security and a library of over 3,000 industrial automation graphics.

PAC Display Professional adds the capability to use redundant scanners and redundant Ethernet links on groov EPIC processors and SNAP PAC controllers. PAC Display Professional also enables logging of SuperTrends, historical logs and runtime operator logging data files to an ODBC database.

The most important new feature with this new release is support for groov EPIC. Its control logic and I/O can be programmed with PAC Control, and customers can use PAC Display to develop a Microsoft Windows-based HMI to run on a separate PC. The groov EPIC’s integrated high-resolution touchscreen is not configured with PAC Display, but is instead configured with groov View software, supplied free with groov EPIC.

New commands added to PAC Control include two specifically for groov EPIC: Get I/O Channel Quality and Get I/O Unit Quality. The groov EPIC I/O modules incorporate LEDs that change color based on the health of the module, revealing data quality to a local technician, and this information can also be configured or retrieved programmatically in control logic using these two new commands.

Another major new feature is full support for MQTT/Sparkplug data communication, provided by Ignition Edge, which is embedded in groov EPIC. MQTT’s publish-subscribe communication architecture is superior to request-response methods, and Sparkplug optimizes MQTT for industrial applications.

Public Access tags are a new PAC Control capability, making it easier and more secure to use MQTT/Sparkplug. During configuration the developer can use Public Access to designate which tags to expose, and to designate each exposed tag for read only or for read-write.

Tags in PAC Control include I/O channels and program variables, some of which can be represented in the Public Access space in more than one way. For example, an integer can be represented as an integer, a Boolean value or an individual bit within the integer. A table can be represented as a table, one element in the table or even one bit of one element—providing a great deal of flexibility in how tags are exposed or protected.

PAC Project Software Suite R10 combines all of the most-needed industrial automation elements, aimed squarely at making it easier for end users to configure control, HMI and communications functionality.

Availability

PAC Project Software Suite R10 will be released on May 18. For additional information and application advice, contact an Opto 22 pre-sales engineer: 951-695-3000 or toll-free, 800-321-6786.

About Opto 22

Opto 22 designs and manufactures industrial control products and Internet of Things platforms that bridge the gap between information technology (IT) and operations technology (OT). Based on a core design philosophy of leveraging open, standards-based technology, Opto 22 products are deployed worldwide in industrial automation, process control, building automation, industrial refrigeration, remote monitoring, and data acquisition applications. Designed and manufactured in the U.S.A., Opto 22 products have a worldwide reputation for ease-of-use, innovation, quality, and reliability. For over 40 years OEMs, machine builders, automation end-users, and information technology and operations personnel have and continue to trust Opto 22 to deliver high-quality products with superior reliability. The company was founded in 1974 and is privately held in Temecula, California, U.S.A. Opto 22 products are available through a global network of distributors and system integrators. For more information, contact Opto 22 headquarters at +1-951-695-3000 or visit www.opto22.com. Follow us on Twitter, Facebook, LinkedIn, YouTube.

Contact:

Janice Colmer, Marketing Specialist

800-321-6786