New NEO Power Skiving Offers Gear Tooth Generating Operation

Press Release Summary:

- Features automatic tool changer, deburring, cutting tool resharpening and automatic loading / unloading

- Includes model 200 and 400 with capacities for parts up to 420 mm diameter and a pitch rating of 4 module

- Uses high quality components such as direct-drive torque motors for the work and cutter spindles, FANUC 0i MF CNC and precision linear scale

Original Press Release:

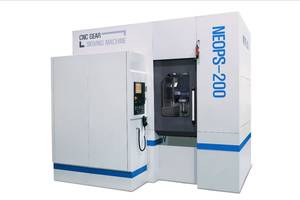

Helios Announces NEO Power Skiving Machine

Helios Gear Products announces a new line of machine tools from YG Tech that serves gear manufacturers seeking a power skiving solution. This line, called “NEO Power Skiving” or “NEOPS,” is the latest affordable innovation brought to the North American market by Helios. “Gear manufacturers for powertrain systems will welcome this new competitor in the marketplace for its affordable price, high technology, productivity, quick delivery, and domestic support,” said Adam Gimpert, President of Helios.

Internal or external spur or helical gears are candidates for power skiving — in particular, those that may traditionally require shaping due to clearance requirements. Compared to shaping, power skiving offers a gear tooth generating operation that is a fraction of the time. Consequently, NEO Power Skiving allows manufacturing gears with a game-changing level of productivity and profitability. This is achieved with a continuous process where the cutting tool is constantly producing small cuts, whereas traditional shaping has unavoidable idle backstrokes that reduce productivity.

The NEO Power Skiving line includes the model 200 and model 400 with capacities for parts up to 420 mm (16.535”) diameter and a pitch rating of 4 module (6.35 DP). The machines use high quality components such as direct-drive torque motors for the work and cutter spindles, FANUC 0i MF CNC, and precision linear scales. Key optional features include automatic tool changer, deburring, cutting tool resharpening, and automatic loading / unloading. The NEOPS 200 and NEOPS 400 offer manufacturers a leading combination of technology and productivity at an affordable price with domestic support.

Additionally, Helios is the fastest-growing supplier of precision gear cutting tools in North America with dedicated application engineers to ensure your power skiving projects are successfully launched and implemented. Helios engineers support and train manufacturers on each application, including workholding strategies, cutting tools and their coatings, machining parameters, automation, and more. Manufacturers new to the power skiving process rely on Helios and are assured profitable success.

Gear manufacturers of high-volume internal or external spur or helical gears must talk to Helios about the new NEO Power Skiving machines. Said David Harroun, Vice President of Helios, “the NEOPS 200 and NEOPS 400 machines offer manufacturers the latest solution for producing profitable gears with the industry’s leading technology, and now this solution is accessible at an affordable price with Helios technical and engineering support.”

About Helios Gear Products, LLC

Helios Gear Products, LLC specializes in the parallel axis gear industry and offers hobbing machines, power skiving machines, worm and thread milling machines, gear inspection equipment, deburring and chamfering machines, automation systems, consumable tools (including hobs, gear grinding and honing wheels), gear tool sharpening machines, and expert services for tool sharpening and part inspection. Helios products are used worldwide, and our experience gives us the edge in contributing to the productivity and profitability of our customers. Helios Gear Products, LLC serves the North American market for YG Tech, Monnier + Zahner / Lambert−Wahli, Tecnomacchine, and Tyrolit−MIRA. Helios also offers cooperative sales and service with Kapp Technologies and Penta Gear Metrology.

Contacts:

Adam Gimpert

President

847-931-4121

agimpert@heliosgearproducts.com