New Mosaic Diamond Grinding Discs are Suitable for Automotive and Aerospace Applications

Press Release Summary:

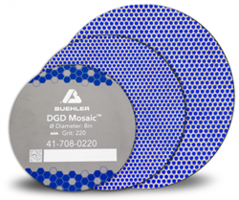

- Available in 8, 10 or 12 in. discs in 120, 220, 320, 400 and 1000 grit sizes with a magnetic backing

- Designed for grinding steel, sintered carbides, alloyed metals, thermal spray coatings and hard materials

- Deliver enhanced material removal rates and extended lifetime

Original Press Release:

Buehler Introduces Mosaic Diamond Grinding Discs for Sample Preparation

The new Diamond Grinding Disc (DGD) Mosaic provides users with an enhanced material removal rate, consistency in results, labor savings and an extended lifetime that saves on repeat purchases.

LAKE BLUFF, ILL. (PRWEB) MARCH 14, 2019 - Buehler is introducing the Mosaic line of diamond grinding discs (DGD) for superb material removal in the grinding process of sample preparation. This is Buehler’s fifth line of DGDs in the grinding consumable offering. The Mosaic DGD is especially suited for demanding laboratories working with heavy duty metals or durable materials.

Buehler developed the high strength abrasive surface of the DGD to effectively grind steel, sintered carbides, alloyed metals, thermal spray coatings, and other hard materials. The new DGD Mosaic provides users with an enhanced material removal rate, consistency in results, labor savings and an extended lifetime that saves on repeat purchases.

The Mosaic DGDs are available with a magnetic backing and come in 8”, 10” or 12” discs in 120, 220, 320, 400 and 1000 grit sizes. For ultimate results, they are partnered with Buehler’s EcoMet or AutoMet family of grinders. The Mosaic DGDs are a time saver for production quality control technicians in many industries including:

- Automotive – Mosaic DGDs are optimal for grinding hard and heat treated steels and other alloyed metals used in the automotive industry.

- Aerospace – They are ideal for super alloys and thermal spray coatings.

- Tool making – In machine shops and they can be used to grind cemented carbides and hard metals.

The extended lifetime of the Buehler Mosaic allows customers to use their DGDs longer before needing replacement and provides a cost effective yet fast and high quality solution for diamond grinding discs.

Mosaic is Buehler’s fifth line of DGDs in the grinding consumable offering. Buehler offers these diamond grinding disc options to meet different application needs:

- DGD Mosaic has high material removal rate and is great for high strength materials and rapid removal of sectioning damage.

- DGD Color has a moderate removal rate for enhanced surface quality, and can be used with the widest range of applications, including soft and ductile materials.

- DGD Terra has a moderate removal rate, excellent flatness, great surface quality, and is ideal for very hard and brittle materials such as ceramics and glass.

- DGD Ultra has moderate removal rate and is good for samples that combine both hard and soft materials and where flatness is critical.

- CGD is a coarse diamond grinding disc, used where the fastest removal rate is needed. An additional post-grinding step is normally used to reduce grinding damage.

All Buehler DGDs are available either directly from Buehler or through a global distributor. Visit http://www.buehler.com/diamond-grinding-discs.php to review the product specifications, options and ordering information.

Buehler, a division of ITW, provides solutions for materials preparation, testing & analysis worldwide. Buehler has been a leading manufacturer of scientific equipment and supplies for research / development and quality control since 1936. Buehler provides equipment and consumables for sectioning, grinding-polishing, mounting and hardness testing. Buehler’s offering is utilized in applications and processes for microstructural analysis of materials in development, incoming or outgoing inspection, production, and failure analysis. For more information, visit https://www.buehler.com/ email marketing@buehler.com.

Contact Information

Perrie Hayes

Buehler

847-295-6500