New Milltronics ChipBossâ„¢ Cuts Cycle Times by up to 50%

Program Conversationally but Cut Like a Boss

Waconia, MN, July 1, 2018 – Milltronics USA, Inc. will debut its new ChipBoss™ software at the International Manufacturing Technology Show (IMTS) in Chicago, Illinois from September 10-15, 2018 (South Building, Booth 338329). This new software lets conversational program users take advantage of the latest trochoidal machining strategies, previously found only in CAM systems or high-end controls.

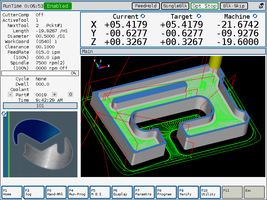

ChipBoss™ uses proprietary algorithms to calculate toolpaths and control maximum allowable cutter engagement. The idea is to use the whole length of a tool rather than just the tip, cutting profiles at full depth rather than taking multiple depth passes. This new optional software works by automatically controlling the tool’s chip load, keeping it constant and creating the optimal chip. This results in faster cycle times, better tool life and more accurate parts. Cycles times (depending on geometry) can be reduced by as much as 50% percent with up to 3-5 times better tool life. ChipBoss™ also improves part accuracy through reduction in tool deflection.

The toolpaths generated by ChipBoss™ are often quite different than what conversational users might be used to – at first glance they might appear inefficient or even erratic. Often the tool path does not even remotely resemble the final shape that is ultimately cut. Additionally, feed rates can be much higher than what conversational program machine users are used to.

The whole idea is to use tool paths that assure a constant chip load – which typically means smaller step overs and bigger depths of cut. And, with ChipBoss™ the goal is to use the whole length of the tool when pocketing or profiling. With conventional conversational programs, the usual machining strategy is to cut the profile using multiple incremental depths and only using the end or tip of the tool. ChipBoss™ uses much more of the flute. This allows the load, heat and wear to be spread out evenly over a much larger area of the tool – resulting in much longer tool life. And it not only maxs out the metal removal and prolongs tool life but is but also is much easier on the machine tool because it reduces the number of times a machine needs to accelerate and decelerate.

Finally, another important feature of the new Milltronics conversational ChipBoss™ software is called “Rest Machining.” Often when machining a part an operator may use a large diameter cutter to remove as much material as possible, dependent on part geometry and features. But typically, some material is left behind because the large cutter won’t fit into an area without cutting material that needs to remain. This leftover material (the “rest”) would then have to be machined with a smaller cutter, wasting time as the whole part gets re-cut just to get to the smaller areas. The new Rest Machining feature calculates the areas to be machined and uses the smaller cutter to get just those areas, saving even more time.

“ChipBoss is another great example of why our customers choose the Milltronic control over industry standard controls,” said Louie Paklakos, Milltronics General Manager. “With industry standard controls, the one you get on day one is the same you’ll always have. With Milltronics, you can add new software like ChipBossTM to an existing machine and not miss out on new advancements as time marches on.”

Milltronics USA, Inc. is based in Waconia, Minn., and is a leading supplier of easy-to-use and cost-effective machine tools serving job shops, tool rooms, tool & die and other metalcutting customers worldwide. With more than 12,000 machines installed, the company was founded in 1973 and has built its reputation on intuitive controls and well-built machines backed by superior service and support. More information is available at www.milltronics.com.