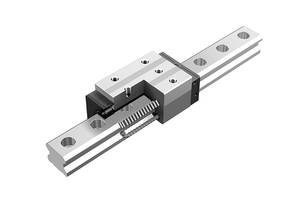

New HRX Roller Distributes Weight along The Roller Diameter and Length

Press Release Summary:

- Features include high rigid, simple structure, caged rollers and an dust proof option

- Retaining design allows for simple interchangeability of the rail and block

- Available in outer dimensions of 48mm to 100mm (H), 100mm to 126mm (W) and 123.2mm to 304.1mm (L)

Original Press Release:

THK Introduces Roller Lm Guide Type HRX for a Range of Applications and Harsh Environments

Schaumburg, IL – THK America, Inc.’s new Roller LM Guide Type HRX is designed to meet the demands of a variety of applications and environments. The Type HRX boasts a duplex face-to-face structure (DF Structure) and a full roller design for resilient performance in even harsh settings. Features include a highly rigid, yet simple structure, caged rollers and an extensive dust proof option.

For high rigidity during heavy loads, the Type HRX roller is designed to evenly distribute weight along the roller diameter and length. Roller performance is further enhanced through the incorporation of Caged Technology.

THK’s Caged Technology employs a synthetic resin cage with a patented curvature that cradles each roller and separates it from the next. The spaces between the rolling elements retain grease and act as a lubrication system for long-term maintenance-free operation. Smooth motion is achieved with the Type HRX, as the separation of balls eliminates friction and minimizes torque fluctuation. This roller retaining design also allows for the easy interchangeability of the rail and the block. Other Caged Technology benefits include low dust generation and reduced wear.

Additionally, four-way equal loading enables the Type HRX to be mounted in any orientation and to meet the requirements of a wide range of applications.

The Type HRX is available in models with outer dimensions of 48mm to 100mm (H), 100mm to 126mm (W) and 123.2mm to 304.1mm (L). Basic load ratings range from 56 to 257 kN.

THK manufactures the widest range of linear motion products, including LM guides, ball screws, mechanical actuators and ball splines and more. All THK products have been designed and manufactured to meet the strictest requirements. THK’s experienced Global Engineering Team can provide customized linear motion solutions from their standard linear motion products as well as from mechatronics products for the most demanding applications.

To learn more, log on to www.thk.com or contact THK America, Inc., 200 E. Commerce Dr., Schaumburg, IL 60173, Phone: (847) 310-1111, Email: marketing@thk.com