New Gasket Tapes for Long-term Sealing of Outdoor Enclosures

Press Release Summary:

- Include R10470-M closed cell silicone sponge, BF-1000 and HT-800 silicone foam materials

- Support the need for high performance silicone sponge and silicone foam gasketing as well as gasket tape roll widths are 500”, 750”, 1.00” and 2.00” wide

- Ideal for industrial ovens and dryers, ventilating and airflow applications

Original Press Release:

Silicone Sponge and Silicone Foam Gasket Tape with DP-1001 Silicone Adhesive is Now Available from Stockwell Elastomerics

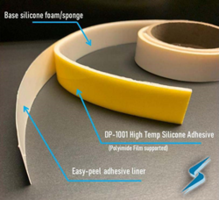

Stockwell Elastomerics, Inc. now offers closed cell silicone sponge and silicone foam adhesive-backed gasket tape with DP-1001 polyimide film supported silicone adhesive backing in slit to width rolls. Materials include R10470-M closed cell silicone sponge, BF-1000 and HT-800 silicone foam.

Philadelphia (PRWeb) June 11, 2020 -- Stockwell Elastomerics announces the availability of silicone sponge and silicone foam gasket tape with DP-1001 silicone adhesive backing. Slit-to-width rolls of these new gasket tapes support the need for high performance silicone sponge and silicone foam gasketing that with proper deflection seals out rain, withstands outdoor conditions and temperature extremes.

Three gasket tape products are initially offered with DP-1001 silicone adhesive: R10470M red/orange closed cell silicone sponge, BF-1000 white, low density silicone foam and HT-800 red, medium density silicone foam. Customers may request a complimentary sample roll of gasket tape with DP-1001 adhesive to evaluate the adhesive properties.

DP-1001 silicone adhesive contains an amber colored polyimide film support layer that provides dimension stability when removing the release liner and installing the gasket strips. The polyimide film layer improves the shelf life of the silicone adhesive backing by preventing migration of the adhesive into the silicone sponge or foam. The polyimide film also withstands a temperature range of -100°F to +500°F, thereby not limiting the performance of the silicone gasket in extreme temperature conditions. DP-1001 silicone adhesive is a total of .005” thick and has an easy peel release liner to aid installation.

“Gasket tape with DP-1001 film supported silicone adhesive provides our customers with high performance silicone sponge and silicone foam gasketing in tape form that can withstand extreme temperatures,” said Stockwell Elastomerics’ President Bill Stockwell. “Further, the polyimide film support and easy peel release liner allows for easier installation than other legacy silicone sponge gaskets with silicone adhesive backing.

These three gasket tape products have been specified for long-term sealing of outdoor enclosures, industrial ovens and dryers, ventilating and airflow applications subject to temperature extremes.

- R10470-M closed cell silicone sponge, provided by Saint-Gobain is UV resistant, will provide long service life in rugged conditions and meets ASTM D6576, Type 2, Grades B and C.

- BF-1000 low density, open cell silicone foam is provided by Rogers Corporation, passes the UL 94V-0 flame rating and is frequently used for air diverting and dust sealing.

- HT-800 medium density, closed cell silicone foam is provided by Rogers Corporation, passes the UL 94V-0 flame rating, UL 50E recompression test and capable of weather sealing when deflected at 35 to 65%.

Any of these gasket tape products can be die cut or water jet cut into custom gaskets if slit-to-width roll materials are not suitable for a sealing requirement. The most frequently specified gasket tape roll widths are .500”, .750”, 1.00” and 2.00” wide. However, any width over .375” is available in custom slit rolls.

More information is available online about all of Stockwell Elastomerics' gasket tape offerings, including a demonstration video, the "Gasket Tape - Silicone Sponge and Silicone Foam for Long Term Sealing Performance" whitepaper, and a request for a tactile brochure and samples.

About Stockwell Elastomerics, Inc.

Stockwell Elastomerics’ core competence is the fabrication and molding of gaskets and pads using silicone rubber, fluorosilicone, and similar high performance elastomers. On-site production capabilities include adhesive lamination, slitting, die cutting, water jet cutting and custom molding. Many Stockwell Elastomerics customers take advantage of water jet cutting and flash cutting for fast turn prototypes and initial production. Stockwell Elastomerics, Inc. is ISO 9001:2015 registered.

Contact Stockwell Elastomerics via the website: https://www.stockwell.com/ for more information and applications assistance.

Contact Information

Bill Stockwell

Stockwell Elastomerics, Inc.

http://https://www.stockwell.com/

215-335-3005