Miscellaneous Fabrics and Cloths

New Film Infusion Capabilities Allow for 3D Woven Joints to Ship as Pre-Made Assemblies

Press Release Summary:

Bally Ribbon Mills recently announced it has expanded its capabilities regarding 3D woven joints to include film infusion. The film infusion process consists of infusing a frozen sheet or film of resin onto the 3D woven joint, allowing the company to ship them as pre-made assemblies. With this not only does the customer save the time and trouble of infusing the resin themselves, Bally Ribbon Mills also gets more control in the 3D woven joint assembly manufacturing process.

Original Press Release:

Bally Ribbon Mills Announces Film Infusion Capabilities for 3-D Woven Joints

Unique capability saves customer processing steps

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, announces its film infusion capabilities for 3-D woven joints. In the film infusion process, a frozen sheet or film of resin is infused onto the custom 3-D woven joint, saving customers the trouble of infusing the resin themselves upon delivery of the BRM-made joint.

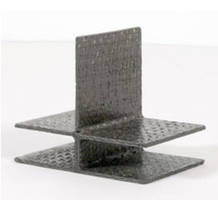

BRM has perfected the science and art of 3-D continuous weaving. Their industry-leading research, design, and fabrication expertise enables them to solve specific challenges in innovative ways. BRM’s Advanced Products Group has developed technologies to fabricate 3-D woven structures such as “Pi – π,” double “T,” “H,” and other complex net shapes. These complex woven structures are used primarily in aerospace applications, often in airframe structural components and subassemblies including stiffeners and joints. They are custom made to fit the application.

BRM uses the film infusion process to infuse a variety of resins to these complex 3-D woven shapes. This ability allows BRM to ship its 3-D woven joints as pre-made assemblies, saving customers processing steps that require time, work, and specialized machinery. BRM’s film infusion capability also allows them to control more steps of the 3-D woven joint assembly manufacturing process, ensuring consistent quality control.

For more information about Bally Ribbon Mills, please visit www.ballyribbon.com

About Bally Ribbon Mills

Bally Ribbon Mills (BRM) designs, develops, and manufactures highly specialized engineered woven webbing, tapes, specialty fabrics, woven preforms, and two dimensional and three dimensional structural fabrics. With more than 95 years of textile manufacturing experience, BRM has earned a reputation for meeting new advanced design challenges. Working in aerospace, defense, medical, safety, automotive, commercial, and industrial applications, BRM offers ingenuity, technical know-how, extensive weaving capabilities, and rigorous quality assurance systems. For more information, visit www.ballyribbon.com or call 610-845-2211.