New Fabric Duct Allows End-Users to View Fabric Type, Printed Technology and Color

Press Release Summary:

- Features custom color and pattern surface printing that reduces custom color costs and cuts waste for color matching in commercial and institutional facilities

- Offers 6 x 4 ft. (1.8 x 1.2 m) fabric palette with 1,100 printed colors for selection

- Plastic suspension hooks, sliders, and air distribution nozzles are available in primary colors, in addition to black and gray

Original Press Release:

FabricAir® Introduces Custom Color and Pattern Surface Printing for Fabric Duct

New Colors & Prints Program (C&PP) expedites ventilation projects by 75-percent, reduces custom color costs, cuts waste and offers an industry-best color matching.

FabricAir®, Lawrenceville, Ga., a leading manufacturer of fabric HVAC duct and accessories, introduces the Colors & Prints Program (C&PP) for quick, affordable and precise surface printing on fabric duct with custom colors, repetitive patterns and graphics. The C&PP expedites custom color and pattern ventilation projects by 75-percent, reduces custom color costs and cuts waste, while offering end-users the industry’s best technology for color matching in commercial and institutional facilities.

The C&PP’s printed custom color segment uses an industry-unique feature of a 6 x 4-foot (1.8 x 1.2-meter) fabric palette with 1,100 printed colors for selection. The palette is shipped free to the end user to match and choose the best color for a cooling, heating or ventilation project. All colors appear differently under various lighting color temperatures and on surface mediums, regardless of CMYK, Pantone TPX, RAL and other specification codes. Therefore, the fabric color palette allows end-users to view the fabric type, printed technology and color under their own unique space lighting conditions to ensure an exact match when interior design and aesthetics are critical. The end-user can also optionally request a larger 8.5 x 11-inch (216 x 279-mm) swatch of the chosen color and fabric for a final matching “what-you-see-is-what-you-get” confirmation and satisfaction.

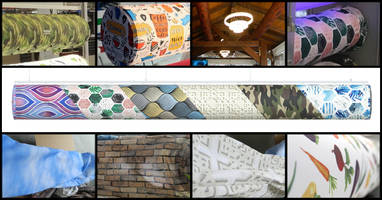

The C&PP’s printed pattern segment offers the end user a nearly infinite number of repetitive patterns available through online stock photo services such as Shutter Stock or Google Search. Using printing technology perfected in the sports apparel industry, FabricAir’s technology can now depict any imaginable repetitive patterns. Some examples are coffee beans for a café, vegetables for a produce department, camo for military facilities or tiger stripes for a zoo exhibit.

Both the printed custom colors and patterns do not affect the fabric’s weight, longevity, form/function, flexibility, NFPA 90A-2018 fire ratings, or the permeability in FabFlow™ designs where air disperses partially through the fabric.

The C&PP complements FabricAir’s existing custom dye color and screen printing graphics processes. The dyeing process takes several weeks of preparation and customer approvals, whereas the C&PP typically only adds one week to the project’s lead time at a fraction of dyed fabric costs. The C&PP also reduces waste, because printing is only on the necessary amount of fabric, versus custom dye processes that require dying entire bolts.

Other C&PP features are:

- Quick affordable and precise;

- Printed colors are best suited for education, office and retail spaces, while printed patterns are popular in supermarkets, retail stores and restaurants;

- Plastic suspension hooks and sliders, plus air distribution nozzles are available in primary colors, in addition to black and gray;

- Laundering doesn’t affect the color or performance of the process;

- Available on Trevira™ as well as Combi™ fabrics, and all dispersion styles;

- Standard warranty based on fabric type. .

For more information on the C&PP or other FabricAir duct and accessories, please visit www.fabricair.com; email sales-US@fabricair.com or contact customer and technical support departments at (502) 493-2210.

About FabricAir: FabricAir designs and produces custom air dispersion & air distribution solutions for a wide range of applications. In 1973 we installed the world’s first fabric ducting system, which heralded a whole new way of thinking within HVAC and indoor climate. We continue to be at the forefront of innovation and proudly deliver superior air dispersion across the globe through sales companies and a substantial distributor network. Our experienced engineers ensure ideal air flow regardless of project complexity. We are headquartered in Denmark and all systems are produced to measure at our facility in Lithuania. For more information on the VarioDuct or other FabricAir duct and accessories, please visit www.fabricair.com; or contact customer and technical support departments at sales-US@fabricair.com or by calling (502) 493-2210.

Contact:

Charles J. Justice - National Sales Mgr

FabricAir

(502) 493-2210

chj@fabricair.com

Or

John Parris Frantz

J.P.F. Communications

(773) 871-2600

john@jpfcomm.com