New EPC Die from Nordson Comes with Deckle Rod Support Guide

Press Release Summary:

- Includes internal deckle system that reduces resin cost and trim waste by controlling edge bead formation, and external deckle for convenient width adjustment

- Offers threaded stud to fine-tune the edge bead and reduces the amount of trim required

- Nut on adjustment rod reduces width and weight of the deckle system, and increases access for operators

Original Press Release:

Enhanced Deckle Design Boosts Productivity of Extrusion Coating Die, Making it Easier to Operate and Maintain

Simplified Mechanisms for Nordson Corporation’s Widely Used EPC™ Die Streamline the Adjustment of Coating Width while Reducing the Size of Edge Bead

CHIPPEWA FALLS, WI, U.S.A., May 5, 2020: Nordson Corporation has streamlined the design of the EPC™ deckle system for EDI® extrusion coating and laminating dies, making it easier to control edge bead and reducing downtime for width changes and cleaning.

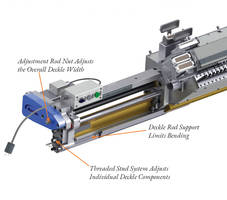

The widely used EPC die includes an internal deckle system that reduces resin cost and trim waste by controlling edge bead formation, plus an external deckle for convenient width adjustment. The new enhanced design provides these improvements:

- Easier control of edge bead. For independent adjustment of the internal deckle components, Nordson has replaced a rack-and-pinion gear with a threaded stud that makes it easier to fine-tune the edge bead, reducing the amount of trim required and increasing material savings.

- Easier manual adjustment of deckle width. Nordson has replaced a gear box used for adjusting overall deckle width with a nut on the adjustment rod, reducing the width and weight of the deckle system and increasing access for operators.

- More robust and user-friendly construction. A durable new deckle rod support guide makes deckle adjustment easier.

- Easier access for cleaning and maintenance. A low-profile external deckle can be removed as a single unit, or it can slide out for installation of a lip scraper without removal of the entire deckle assembly. Similarly, internal deckle components can be taken out by removing six bolts from the end of the deckle system without disengaging the entire unit.

“The enhancements that Nordson has designed into the EPC system address concerns voiced to us by converters—particularly the competitive pressure to maximize productivity,” said Patrick Meinen, global product line manager for EDI dies. “Our new-design extrusion coating dies are easier to operate and maintain, while providing the same effective control over edge bead that has been the distinguishing value of the EPC system.”

The internal deckle system in an EPC die provides fine-tuning of the edge profile of a coating. The molten polymer in a die without an EPC deckle system will exhibit transverse flow, producing an enlarged edge bead from the resulting necking at the die exit. In the EPC system, the internal deckle components for adjusting the edge bead profile are located downstream of the primary manifold—one in the preland section, the second in the secondary manifold. By adjusting the positions of these components relative to one another, it is possible to reduce the flow of polymer at the extreme edges of the coating, thereby minimizing edge bead.

Nordson Corporation engineers, manufactures and markets differentiated products and systems used for the precision dispensing of adhesives, coatings, sealants, biomaterials, polymers, plastics and other materials, fluid management, test and inspection, UV curing and plasma surface treatment, all supported by application expertise and direct global sales and service. Nordson serves a wide variety of consumer non-durable, durable and technology end markets including packaging, nonwovens, electronics, medical, appliances, energy, transportation, construction, and general product assembly and finishing. Founded in 1954 and headquartered in Westlake, Ohio, the company has operations and support offices in more than 30 countries. Visit Nordson on the web at http://www.nordson.com, @Nordson_Corp, or www.facebook.com/nordson.

Nordson Polymer Processing Systems provides customers with engineered components to melt, homogenize, filter, meter, and give shape to plastic and fluid coating materials. Nordson Corporation leverages the collective plastics industry experience from a series of strategic acquisitions to offer a uniquely broad portfolio of industry-leading technologies. Nordson delivers a full range of precision melt stream products — from screws and barrels for extrusion and injection molding — to filtration systems, pumps, and valves — to the extrusion dies and pelletizing systems to meet the constantly evolving needs of the polymer industry.

Nordson Corporation provides customers with local technical sales, service and remanufacturing capabilities through sales organizations and regional manufacturing facilities in over 30 countries. To learn more visit us at http://www.nordsonpolymerprocessing.com, https://www.linkedin.com/company/nordson-polymer-processing-systems/, www.facebook.com/NordsonPPS.

Press Contacts:

Robert J. Martino

Martino Communications Inc.

Tel: 1-203-321-0787

Email: bob@martinocommunications.com