Material Handling and Storage Racks

New Customizable Shipping Racks with Collapsible Side Design Reduces Space and Freight Costs

Press Release Summary:

- Ideal for reducing damage and loss when shipping fragile vehicle parts for final vehicle assembly

- Help cube out a trailer maximizing the number of parts that can be handled in each truckload

- Rack options are available bumper fascia and front ends, doors, driveshafts and axles, engines, fairing, fenders, front assembly, headliners and hood racks

Original Press Release:

Steel King Announces Shipping Racks to Safely Ship Vehicle Parts Without Loss or Damage

Customizable solutions reduce freight costs by maximizing number of parts per truckload

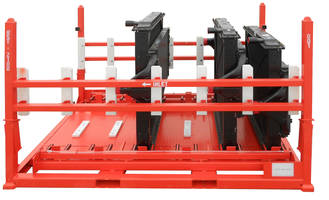

Steel King Industries, Inc., a leading manufacturer of material handling products and systems for improving operational efficiency, announces a diverse line of highly customizable shipping racks, ideal for reducing damage and loss when shipping fragile vehicle parts for final vehicle assembly. Steel King’s custom shipping racks help users “cube out” a trailer, maximizing the number of parts that can be handled in each truckload. This can significantly reduce freight costs. The racks also cut costs associated with disposable pallets. Shipping racks and containers can often be designed with collapsible sides to allow empty racks to reduce space and freight costs on the return trip.

From steering wheels, mirrors, and fenders to engines and transmissions, Steel King builds racks that maximize trailer space by using a variety of stacking or space-saving designs. In addition to the steel-framed racks, Steel King designs all dunnage needed to cradle, cushion, or support the parts and integrates the dunnage into the rack.

The line of Steel King shipping racks are a great choice for manufacturers redesigning truck fleets to be more aerodynamic to meet National Highway Traffic Safety Administration (NHTSA) and Environmental Protection Agency (EPA) fuel economy requirements.

Steel King offers in-house engineering, design, prototyping, laser/plasma cutting, CNC machining, welding, powder coating and assembling, Starting with the part or prototype, design experts use a unique process to develop a completely customized application-specific solution to ensure products are handled delicately and not scratched, dented, or broken.

Transport/custom product rack options are available for bumper fascia and front ends, doors, driveshafts and axles, engines, fairing, fenders, front assembly, headliners, and hood racks. Also available are racks for industrial carts, kits, metal stampings, muffler exhausts, tires, and many others.

For more information about Steel King’s shipping racks, visit: www.steelking.com/shipping-racks.

About Us

Steel King Industries, Inc., is a leading manufacturer and integrator of material handling products and systems for improving operational efficiency in manufacturing, assembly, distribution centers, storage facilities, and warehousing.

Steel King is the nation’s only single-source manufacturer of pallet racks, drive in rack, flow rack, pushback rack, pick modules, mezzanines, cantilever racks, portable racks, industrial containers, custom shipping racks, and industrial safety guard railing.

Uniquely qualified to assist customers in planning and executing material handling systems, Steel King delivers reduced operation costs and increased customer satisfaction across a range of applications.

For additional information visit www.steelking.com or call 800.826.0203.