New Constant Pass-Line Distance System Monitors Correct Winding Process

Press Release Summary:

- Features a distance meter that automatically controls the distance to the strip surface

- Monitors the rewinding process and adherence to the specified tolerances

- Installed in front of or directly behind the coiler and moved accordingly with each change in distance

Original Press Release:

Quality Inspection in Space-Critical Lines - New Innovation Makes it Possible to Inspect at the Coiler

100% inspection: Movable sensor keeps constant distance to the metal strip

The constant distance between the sensor and the strip surface is a mandatory requirement for the fully automatic quality control of steel and aluminium strips. Changing distances such as at the coiler made reliable images so far impossible. The optional extension of an inspection system now ensures a stable distance between the sensor and the object - thus opening up completely new installation locations.

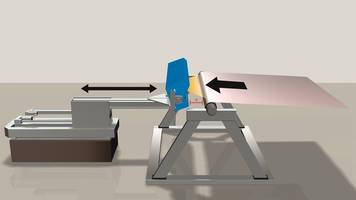

With the Constant Pass-line Distance Technology (CPD), ISRA VISION PARSYTEC presents a product extension of the already wellproven SURFACE MASTER. While these systems are usually installed fix, the sensor can be moved thanks to the CPD extension. The sensor distance to the inspected surface is thus automatically kept constant. This opens up new possibilities for installation, especially in cramped spaces - wherever the so-called pass-line, ie the distance between the metal strip and a permanently installed system, changes.

Quality inspection immediately before delivery

Varies the distance between the metal surface and the camera, the sensor is not suitable for a reliable inspection. With the CPD extension, the available space on the coiler now becomes an option for installation. Since the rolling up of the metal strip causes the diameter of the coil to increase in layers, an inspection is only possible if the inspection system adapts equally to the distance. At the end of the production process, a quality inspection ensures maximum certainty about the final quality. Immediately before delivery, all details of the product are documented and further defects hardly arise. In addition, the inspection at this point remains largely unaffected by environmental influences such as dirt, dust or water vapor, which enables precise and reliable inspection results.

Distance measurement, rewind control and robust inspection

The CPD system extension has a distance meter that controls the distance to the strip surface fully automatically. This is especially necessary when strip layers are rolled up on the coil. The inspection system is installed in front of or directly behind the coiler and moves accordingly with each new change in distance. The CPD extension now allows inspection at new locations that often allow visual inspection for the first time. Thus, a complete documentation is available for all production lines, for quick quality proof to customers.

In addition, CPD also monitors the correct winding process: Since metal strip coils are not always rolled exactly centric, a certain "telescope effect" can occur. The CPD inspection extension monitors the rewinding process and adherence to specified tolerances. If these are exceeded, the system warns the plant operator so that he can react immediately. This ensures that only 100% checked and correctly wound goods reach the customer. In addition, the online presentation of the inspection results enables direct conclusions to be drawn on the process quality and thus creates the basis for production optimization. This reduces costs sustainably and increases the total yield of a production line. State-of-the-art camera and lighting techniques ensure razor-sharp defect images. Combined with the sophisticated software, the detection and classification of all defects becomes highly reliable.

Complete portfolio for the entire process chain - product enhancements increase efficiency

The Constant Pass-line Distance technology is one of many system extensions that make an inspection with ISRA's SURFACE MASTER even more flexible. With additional product options, users also gain additional efficiency potential in their lines: for example, the detection of periodic roll mark defects before they become visible saves material and rework and a sensor that can be moved laterally off the line facilitates maintenance and system updates. For automated quality assurance from the beginning of the production chain, the SLAB MASTER and PLATE MASTER systems are also available. ISRA's portfolio is rounded off by the EXPERT5i software modules, which use the collected inspection data to actively demonstrate optimization potential.

Contact: Clemens Petzold

E-Mail: cpetzold@isravision.com

Phone: +49 (0)6151 948 - 609