New CoLOS OEE Software Enables 10-15% Gains in Production Efficiency

Press Release Summary:

- Allow users to access real-time and historical packaging line data, targeting key availability, performance and quality losses as well as bottlenecks

- Collects data from existing Markem-Image coders or any OPC-enabled packaging line devices, at two points along the line, with no need for extra hardware or communications

- Suitable for multi-step approach from one line to full-site deployment

Original Press Release:

Markem-imaje Introduces New CoLOS® Overall Equipment Effectiveness Software

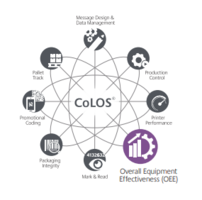

Downers Grove, Ill., Dec. 10, 2019 /PRNewswire/ -- Markem-Imaje, part of Dover (NYSE: DOV), is launching a new CoLOS® Overall Equipment Effectiveness (OEE) software application which enables 10-15% gains in production efficiency. The new software will allow manufacturers to more easily access real-time and historical packaging line data, targeting key availability, performance and quality losses, as well as bottlenecks. Easy to implement in days, it empowers companies not only to take the right corrective action quickly but also to continuously monitor line efficiency key performance indicators (KPIs) and implement improvements.

Tackling high downtime, low performance and poor quality is a priority for all manufacturers. One way to increase efficiency is to measure and improve OEE, a standard method measuring manufacturing productivity composed of 3 KPIs: Availability, Performance and Quality. Many OEE solutions can be expensive and time-consuming to implement, as they require custom programming or the expertise to undertake complicated configuration. CoLOS OEE, by contrast, is an off-the-shelf application that is 100% configurable and provides the insights needed to improve efficiency within days of purchase. This software by Markem-Imaje is suitable for a multi-step approach from one line to full-site deployment.

Key Challenge Measuring and Improving OEE:

Typical OEE rates before continuous improvement program implementation are 50-60%. While best-in-class plants achieve 85% OEE rates, many struggle with improving their figures as they do not have easy, timely and comprehensive access to the information they need to calculate and track effectively.

A Quicker, Easier Way to Calculate OEE and Optimize Line Efficiency:

Positive feedback has been received by customers testing the software in its development phase. "We can now make better data-driven decisions to implement line improvements," says Todd Mondry, Vice President of Engineering and Operations, Red River Commodities. "CoLOS OEE has proved so effective that we're planning to deploy it across all our factories. In fact, I'm regularly asked by plants for updates on when they can deploy it at their location."

Because it is part of the market-leading CoLOS information management system, the new OEE collects data from existing Markem-Imaje coders, or any OPC-enabled packaging line devices, at two points along the line, with no need for extra hardware or communications.

By analyzing the data collected at these points, CoLOS automatically calculates the OEE KPIs which are defined as the following ratios:

- Availability: real versus planned production time

- Performance: real versus theoretical maximum line rate

- Quality: good versus total products produced

These KPIs are displayed on real-time dashboards, helping operators ensure their lines produce the maximum number of high-quality products, taking into account planned downtime and stops.

If a line stops unexpectedly, for example, the counters will pause. This is reflected on the dashboards, alerting operators who can fix the issue immediately. Once the problem has been identified and rectified, the operator can select the relevant reason on the user interface to facilitate further analysis. Alternatively, if the feature is enabled, CoLOS OEE can get the error code data automatically from the relevant packaging line devices.

Providing Insight that Identifies the Root Causes of Inefficiency:

CoLOS OEE provides a variety of historical reports so managers have the facts they need to enhance productivity permanently by prioritizing and eliminating the top reasons for downtime, performance and quality losses. Quickly and continuously they can identify trends and fix the root cause of issues to achieve greater efficiency gains of up to 10-15%. Used with Markem-Imaje's other Packaging Intelligence solutions, efficiency can be improved even further.

"You can't improve what you don't measure and taking data-driven decisions reduces risk while substantially increasing chances of a successful outcome," observes Mark Hathaway, CoLOS Software Product Manager, Markem-Imaje. "Manually collecting the information needed to implement the right changes, however, is time-consuming and subject to human error. Custom automation improves accuracy but can take years to develop. Our launch opens the door to any company ─small, medium or large, with or without the funds or time for a long development process─ who wants to improve their OEE. Our tool is easy to use and install, plus it provides the detailed data needed to drive big increases in production efficiency," adds Hathaway.

For more information, please visit: www.markem-imaje.com/colos-oee.

About Markem-Imaje:

Markem-Imaje, a wholly-owned subsidiary of the US-based Dover Corporation, is a trusted world manufacturer of product identification and traceability solutions, offering a full line of reliable and innovative inkjet, thermal transfer, laser, and print and apply label systems. Markem-Imaje provides global reach to over 50,000 customers with 30 subsidiaries, 6 technology centers, several equipment repair centers and manufacturing plants with the most comprehensive marking and coding portfolio available in the marketplace. Visit www.markem-imaje.com for further information.

About Dover:

Dover is a diversified global manufacturer with annual revenue of approximately $7 billion. We deliver innovative equipment and components, specialty systems, consumable supplies, software and digital solutions, and support services through five operating segments: Engineered Products, Fueling Solutions, Imaging & Identification, Pumps & Process Solutions and Refrigeration & Food Equipment. Dover combines global scale with operational agility to lead the markets we serve. Recognized for our entrepreneurial approach for over 60 years, our team of approximately 24,000 employees takes an ownership mindset, collaborating with customers to redefine what's possible. Headquartered in Downers Grove, Illinois, Dover trades on the New York Stock Exchange under "DOV." Additional information is available at dovercorporation.com.

Markem-Imaje Contact:

Christine Bonnet

Global Communications Specialist

33 (0)4 75 75 55 16

cbonnet@markem-imaje.com

Dover Media Contact:

Adrian Sakowicz

VP, Communications

(630) 743-5039

asakowicz@dovercorp.com

Dover Investor Contact:

Andrey Galiuk

VP, Corporate Development and Investor Relations

(630) 743-5131

agaliuk@dovercorp.com

Source Dover

Web Site: http://www.dovercorporation.com