New AlphaGRAFT DBM Fiber Technology Improves Regenerative Capacity

Press Release Summary:

- Optimized handling enables combination with allograft or autograft for use in spinal fusion procedures

- Provides moldable allograft with cohesive handling characteristics and osteoconductive scaffold for delivery of autologous stem cells

- Regenerative capacity exhibits all five elements of new bone formation in validated animal models

Original Press Release:

Alphatec Announces Commercial Launch of PLIF IdentiTi™ Posterior Straight Porous Titanium Interbody System Implant and AlphaGRAFT® DBM Fiber

Carlsbad, Calif., May 06, 2019 (Globe Newswire) -- Alphatec Holdings, Inc. (“ATEC” or the “Company”) (Nasdaq: ATEC), a medical device company dedicated to revolutionizing the approach to spine surgery, announced today the commercial releases of its PLIF IdentiTi-PS Porous Titanium Interbody Implant System for Posterior Lumbar Interbody Fusion Procedures (PLIFs) and its AlphaGRAFT Demineralized Bone Matrix (DBM) Fiber.

“These new product launches are a direct reflection of the unmatched spine expertise we have amassed at ATEC,” said Pat Miles, Chairman and Chief Executive Officer. “Our teams are rapidly architecting technology that improves surgical outcomes. The ATEC innovation machine will launch 12 new products in 2019, including these offerings – an exceptional number by any industry standard.”

IdentiTi-PS Porous Titanium Interbody Implant System

The launch of the IdentiTi-PS Interbody Implant System follows successful alpha evaluations that began in June 2018. It marks the second of six IdentiTi implant systems the Company expects to commercially introduce in 2019.

The IdentiTi line of implant systems, with enhanced imaging characteristics and porosity, are expected to provide performance that is superior to competitive titanium implant offerings. The IdentiTi line of implants will not only complement the Company’s current suite of PEEK implants, but will also allow ATEC to address the broader market of surgeons who prefer titanium.

“The IdentiTi-PS implant represents the next evolution in porous titanium interbody implants,” added David G. Schwartz, MD, MBA, of OrthoIndy and Indiana University School of Medicine. “IdentiTi implants have a porosity and stiffness similar to bone, properties conducive to new bone growth, with minimal imaging scatter across all radiographic modalities.”

“Achieving sagittal balance from a posterior approach can be challenging with most traditional implant options,” commented David S. Jones, MD, of Carolina Neurosurgery and Spine Associates. “IdentiTi-PS implants were designed to insert the implant on its side and then rotate up, which is a powerful lordosis-inducing maneuver with 15- and 20-degree implant options.”

Key Features of the IdentiTi Porous Titanium Interbody Systems

ATEC’s IdentiTi Porous TI Interbody Systems offer implant options that take advantage of bone’s affinity for titanium. Because of their porosity, IdentiTi implants have a surface roughness that enhances stability. The implants are also designed to provide the biological, biomechanical, and imaging characteristics that surgeons seek in a fusion construct.

Key features include:

- Consistent, fully interconnected porosity throughout the implant, designed to mimic the structure and porosity of cancellous bone;

- Proprietary pore structure designed to create surface roughness that enhances immediate implant stability and facilitates surface adhesion;

- Reduced density (60% porous), which enhances intraoperative and postoperative imaging;

- Stiffness similar to bone;

- Subtractive manufacturing process, creating consistent and reproducible interconnected pore sizes, which leads to predictable performance across the IdentiTi family of implants; and

- Intuitive, low profile, and exacting instruments designed to optimize the surgeon experience and facilitate outstanding patient outcomes.

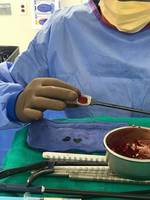

AlphaGRAFT DBM Fiber Technology

Demineralized Bone Matrix (“DBM”) is a standard in the market for bone graft substitutes, or “biologics” products, which are used as an alternative to the patient’s own bone (autograft) in spine fusion procedures. ATEC designed AlphaGRAFT DBM Fiber to combine the regenerative capacity of interconnected fibers with the maximum availability of growth factors endogenous to bone. Composed entirely of demineralized fibers, AlphaGRAFT DBM offers a unique, moldable allograft with cohesive handling characteristics and an osteoconductive scaffold for the delivery of autologous stem cells.

“The AlphaGRAFT DBM Fiber is my new go-to biologic for all my MIS interbody fusions. There is no required defrost or decanting time, it is easily rehydrated with local blood, bone marrow or venous drawn blood, and if I need more, we just peel open another package,” remarked Ray Oshtory, MD, of Pacific Heights Spine Center in San Francisco, California. “In the past, I was wary of letting the scrub tech prepare the biologic as I wanted to make sure I liked the mixture of chips, putty, cellular, etc.; but with the fibers, they are so easily moldable and cohesive, I can prepare the endplates while the scrub tech prepares the biologic and implant, saving time and frustration. I feel more confident in the fusion because the demineralization exposes osteoinductive growth factors within the osteoconductive fiber network.”

Key Features of AlphaGRAFT DBM Fiber Technology

- Optimized handling, enabling combination with allograft or autograft for use in spinal fusion procedures;

- Engineering that enhances regenerative capacity compared to particulate DBM;

- 100% demineralized fibers, to expose innate osteoinductive growth factors;

- Delivery of osteogenic cells, when hydrated with the patient’s bone marrow aspirate; and

- Proven regenerative capacity, exhibiting all five elements of new bone formation in validated animal models.

About Alphatec Holdings, Inc.

Alphatec Holdings, Inc., through its wholly-owned subsidiaries, Alphatec Spine, Inc. and SafeOp Surgical, Inc., is a medical device company dedicated to revolutionizing the approach to spine surgery. ATEC designs, develops and markets spinal fusion technology products and solutions for the treatment of spinal disorders associated with disease and degeneration, congenital deformities and trauma. The Company markets its products in the U.S. via independent sales agents and a direct sales force.

Additional information can be found at www.atecspine.com.

Investor/Media Contact:

Tina Jacobsen

Investor Relations

(760) 494-6790

Company Contact:

Jeff Black

Chief Financial Officer

Alphatec Holdings, Inc.