New AgieCharmilles Laser S Series Texturing Solutions Reduce the Risk of Human Error

Press Release Summary:

- Suitable for difficult-to-realize designs texturing applications in industries such as automotive and ICT packaging

- Controls the cost per part, reduces leads and machining times and improves the quality

- Slashes fine surface-texturing time for a range of parts and applications

Original Press Release:

New Laser S Series Boosts Surface Texturing Quality and Productivity

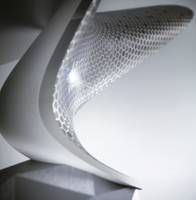

LINCOLNSHIRE, Ill., February 14, 2019 – Shops that need a highly efficient digital solution to surface texturing for product design and mold making will gain new levels of design quality and productivity with the new AgieCharmilles LASER S series from GF Machining Solutions. This all-in-one texturing solution applies designs to challenging surfaces while it controls cost per part, cuts lead and machining times and significantly improves quality. Benchmarking tests show that in a single setup, the LASER S series not only reduces the risk of human error, it also slashes fine surface-texturing time for a wider range of parts and applications.

As part of the digital transformation in manufacturing, the AgieCharmilles LASER S series provides a fully digital solution to the limitations of conventional and manual surface texturing methods to reduce quality deviations without additional machining processes. On the tenth anniversary of the introduction of the AgieCharmilles LASER family, the new AgieCharmilles LASER S makes difficult-to-realize designs easy to generate for more creative freedom and faster time to market, especially in industries such as automotive, information and communications technology (ICT) and packaging.

The AgieCharmilles LASER S series debuts February 27, 2019 in Asia, reaches Europe in March and the North American market in April.

About GF Machining Solutions

GF Machining Solutions is the world’s leading provider of machines, diverse technical solutions and services not only to the tool and mold making industry but also to manufacturers of precision components. The portfolio ranges from electrical discharge machines, high-speed and high-performance milling machines – including clamping and palletization systems, 3D laser surface texturing machines and Spindles – to solutions for tooling and automation, services, spare parts, expendable parts, consumables and digitalization solutions. GF Machining Solutions is a globally acting Division of the Georg Fischer Group (Switzerland) and maintains a presence on 50 sites worldwide within its own organization. Its 3,255 employees generated sales of CHF 992 million in 2017. More information can be found at www.gfms.com.

MEDIA CONTACTS:

Karl Kleppek

Director of Business Development

GF Machining Solutions LLC

847.955.7164 | karl.kleppek@georgfischer.com

or

Chuck Bates

Vice President

dgs Marketing Engineers®

317.813.2230 | bates@dgsmarketing.com