Waterjet Cutters and Cutting Machinery

New Abrasive Waterjets Come with Intelli-MAX Operating Software

Press Release Summary:

OMAX’s Cutting-Edge Abrasive waterjets include OMAX 80X, a GlobalMAX® 1530 and compact ProtoMAX® models. The OMAX’s 80X series Jetmachining centers feature multiple table sizes and customizable work envelope. The GlobalMAX unit is equipped with 10 HP direct drive pump that delivers 30,000 psi pressure and is suitable for educators, job shops, fabricators and manufacturers. The Intelli-MAX® software is compatible with different file formats such as .jpg, .gif, and .png files.

Original Press Release:

OMAX® To Demonstrate Cutting-edge Abrasive Waterjets at FABTECH 2018

KENT, Wash., August 24, 2018 – At Fabtech 2018, OMAX® Corporation will demonstrate cutting-edge abrasive waterjet technology. Visitors to the OMAX booth (B6951) will get a first-hand look at OMAX’s 80X with a Tilt-A-Jet®, Rotary, and 100hp EnduroMAX® pump; a GlobalMAX® 1530 with the new 10hp pump and 100lb garnet feed hopper; as well as the new compact ProtoMAX®. With a wide range of machines as well as productivity-enhancing accessories, OMAX has a waterjet for every fabricating and manufacturing need.

Experience OMAX’s easy-to-operate software, Intelli-MAX®. Intelli-MAX was engineered specifically for abrasive waterjets and no special machine code knowledge is required to use it. Online training for machine operation and maintenance is provided free, so customers can access training information whenever they need it and at their own pace. In addition to being easy to use, Intelli-MAX software is compatible with more than 90 different file formats, including all major CAD program file types, plus graphics file formats such as .jpg, .gif, and .png files. This means almost any 2D or 3D part file can be imported directly into an OMAX waterjet controller and turned into a real part.

OMAX Corporation’s 80X Series JetMachining® Centers incorporate multiple table sizes and a customizable work envelope for precise abrasive waterjet cutting of large-scale components and multi-part projects. The Tilt-A-Jet’s advanced automated taper compensation attains virtually zero taper for the precision cutting of parts with square, taper-free edges, including interlocking pieces and dovetail fittings, all while maintaining extremely high cutting rates. With the water-resistant Rotary Axis head for complex 3D parts production, the 80X’s capabilities expand to cut in as many as 6 axes.

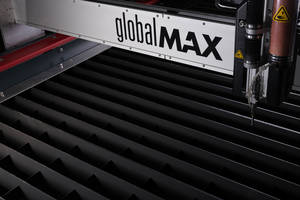

Designed for educators, job shops, fabricators, and manufacturers who need an economical, industrial abrasive waterjet, the GlobalMAX with the new 10hp direct drive pump delivers 30,000 psi pressure to the cutting nozzle. The addition of the 100lb bulk abrasive delivery system supplies garnet for long cuts. The combination GlobalMAX with the 10HP pump is priced as low as the mid $50,000s USD – or under $1,000 USD per month financed.

ProtoMAX is a compact, self-contained cutting system ideally suited for prototyping and low-volume cutting of almost any material approximately 1" thick. Bringing all the versatility benefits of large abrasive waterjets together in a sleek and economic package, this machine is perfect for small job shops, engineering classrooms, makerspaces and personal use. It is also a useful addition for large shops and fabricators that need occasional waterjet capabilities to complement their other cutting systems.

OMAX application specialists and certified technicians will be on hand at FABTECH 2018 to answer all of your abrasive waterjet questions and help find the OMAX system suited to your application.

About OMAX Corporation

Based in Kent, Washington, OMAX Corporation is the global leader in advanced abrasive waterjet systems that cut virtually any material and thickness with unmatched speed and accuracy. Owner of the OMAX and MAXIEM brands, the company provides a comprehensive selection of JetMachining Centers that feature intuitive software controls and incorporate the most efficient pump technology available. In developing its machines, the company designs, manufactures, assembles and tests components as a complete system to ensure optimum performance. The company also has the most comprehensive service and support network in the waterjet industry to keep its customers ahead of the manufacturing curve. For more information, visit OMAX.com or connect with the company on Facebook, Twitter, LinkedIn and YouTube.

MEDIA CONTACTS:

OMAX® Corporation

Stephen Bruner

Vice President of Marketing

253.872.2300 | stephen.bruner@omax.com

or

dgs Marketing Engineers®

Chuck Bates

Director of Public Relations

317.813.2230 | bates@dgsmarketing.com